Blog

What is a Chemical Pump? Understanding Types, Uses, and Benefits for Your Industry

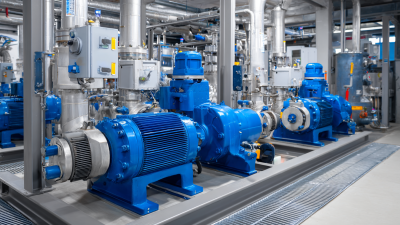

A chemical pump is an essential piece of equipment designed to transport various types of fluids, particularly chemicals, in a range of industrial applications. Understanding the different types of chemical pumps, their uses, and the benefits they offer can greatly enhance operational efficiency and safety in your industry. From transferring corrosive liquids to handling viscous materials, these pumps are tailored to meet specific fluid characteristics and operational demands.

In today's rapidly evolving industrial landscape, selecting the right chemical pump is critical for maintaining productivity and ensuring safety standards. The various types of chemical pumps, including diaphragm pumps, centrifugal pumps, and peristaltic pumps, each serve distinct purposes and offer unique advantages based on the application's requirements. This article will delve into the intricacies of chemical pumps, providing valuable insights on how to choose the most suitable option for your operations, while also highlighting the benefits these pumps bring to your industrial processes. Through strategic selection and implementation of chemical pumps, businesses can optimize their fluid handling capabilities, reduce downtime, and increase overall efficiency.

Understanding Chemical Pumps: Definition and Functionality

Chemical pumps are specialized devices designed to transport various types of fluids, including corrosive and hazardous materials, from one location to another within industrial settings. The primary functionality of these pumps is to overcome the resistance posed by the fluid's viscosity, pressure, and temperature, ensuring efficient movement through piping systems. According to a report by MarketsandMarkets, the global chemical pump market is projected to reach $34.99 billion by 2027, driven by increasing demand across industries such as chemical processing, water and wastewater treatment, and pharmaceuticals.

There are several types of chemical pumps, including centrifugal, diaphragm, and peristaltic pumps, each catering to specific applications and fluid characteristics. For instance, centrifugal pumps are favored for their ability to handle large volumes of fluid at low viscosity, while diaphragm pumps are ideal for metering and handling viscous or abrasive fluids. The versatility of chemical pumps allows industries to enhance the efficiency of their operations, reduce downtime, and improve safety standards by minimizing leaks and spills, which can lead to environmental hazards. According to a study by Grand View Research, advancements in pump technology could lead to a projected compound annual growth rate (CAGR) of 4.3% from 2020 to 2027, reflecting the growing significance of chemical pumps in modern industrial applications.

Key Types of Chemical Pumps: A Comprehensive Breakdown

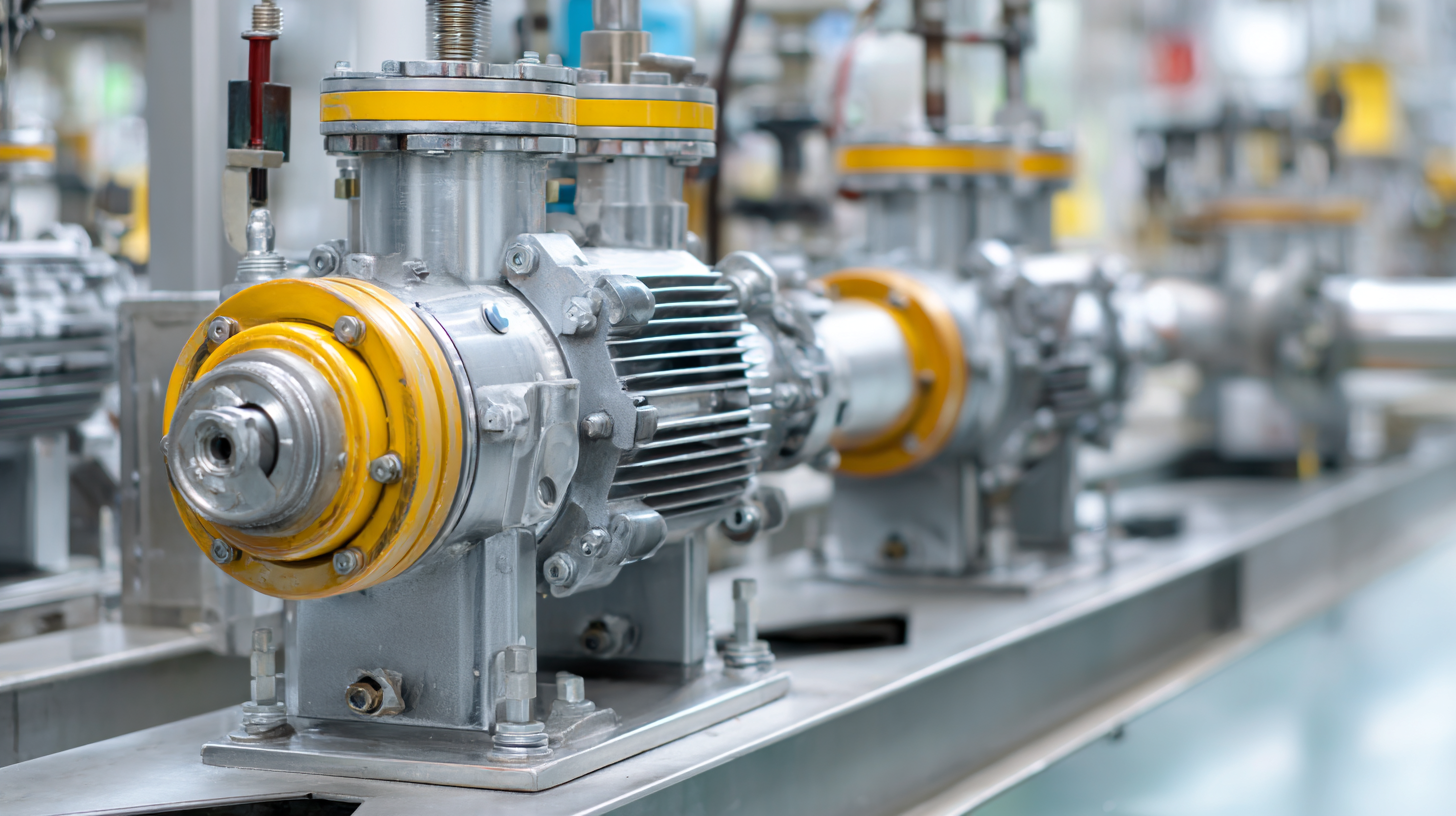

Chemical pumps are essential components in industries that require the transfer of corrosive or hazardous liquids. Understanding the key types of chemical pumps is crucial for optimizing operations and ensuring safety in handling chemical substances. The most common types include centrifugal pumps, diaphragm pumps, and gear pumps, each serving unique functions depending on the application.

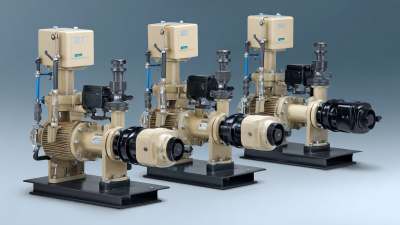

Centrifugal pumps utilize a rotating impeller to move fluids, making them ideal for large volumes of low-viscosity chemicals. They are widely used in water treatment and chemical processing industries due to their efficiency and ability to handle a variety of fluid types. On the other hand, diaphragm pumps employ a flexible diaphragm to create a pumping action, which allows for safe handling of aggressive chemicals, including slurries and viscous liquids. Gear pumps, known for their precision, are employed in applications requiring accurate dosing of fluids, often found in the pharmaceutical and food industries. Each type of pump brings distinct benefits, making it essential to choose the right one based on the specific needs of the industry.

Types of Chemical Pumps and Their Applications

This chart illustrates the distribution of various types of chemical pumps according to their applications across different industries. Centrifugal pumps are the most widely used, benefiting from their efficiency and suitability for various liquids.

Applications of Chemical Pumps Across Various Industries

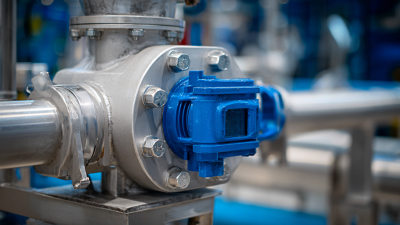

Chemical pumps play a crucial role in a variety of industries, facilitating the safe and efficient transfer of corrosive and hazardous fluids. For example, in the oil and gas sector, chemical pumps are essential for handling substances like crude oil and various process chemicals. According to a report by MarketsandMarkets, the global chemical pump market was valued at approximately $3.8 billion in 2020, with projections indicating substantial growth driven by increasing demand in these key sectors.

In the water treatment industry, chemical pumps are vital for dosing applications, such as adding coagulants or disinfectants to drinking water. The American Water Works Association (AWWA) notes that effective chemical dosing can enhance water quality and ensure public health safety. Furthermore, the pharmaceutical industry relies heavily on precision chemical pumps to ensure accurate dosing of drug formulations. A market research report by Grand View Research found that the global pharmaceutical pumps market is expected to reach $3.95 billion by 2027, primarily due to the increased demand for effective and reliable pumping solutions.

Benefits of Utilizing Chemical Pumps in Industrial Processes

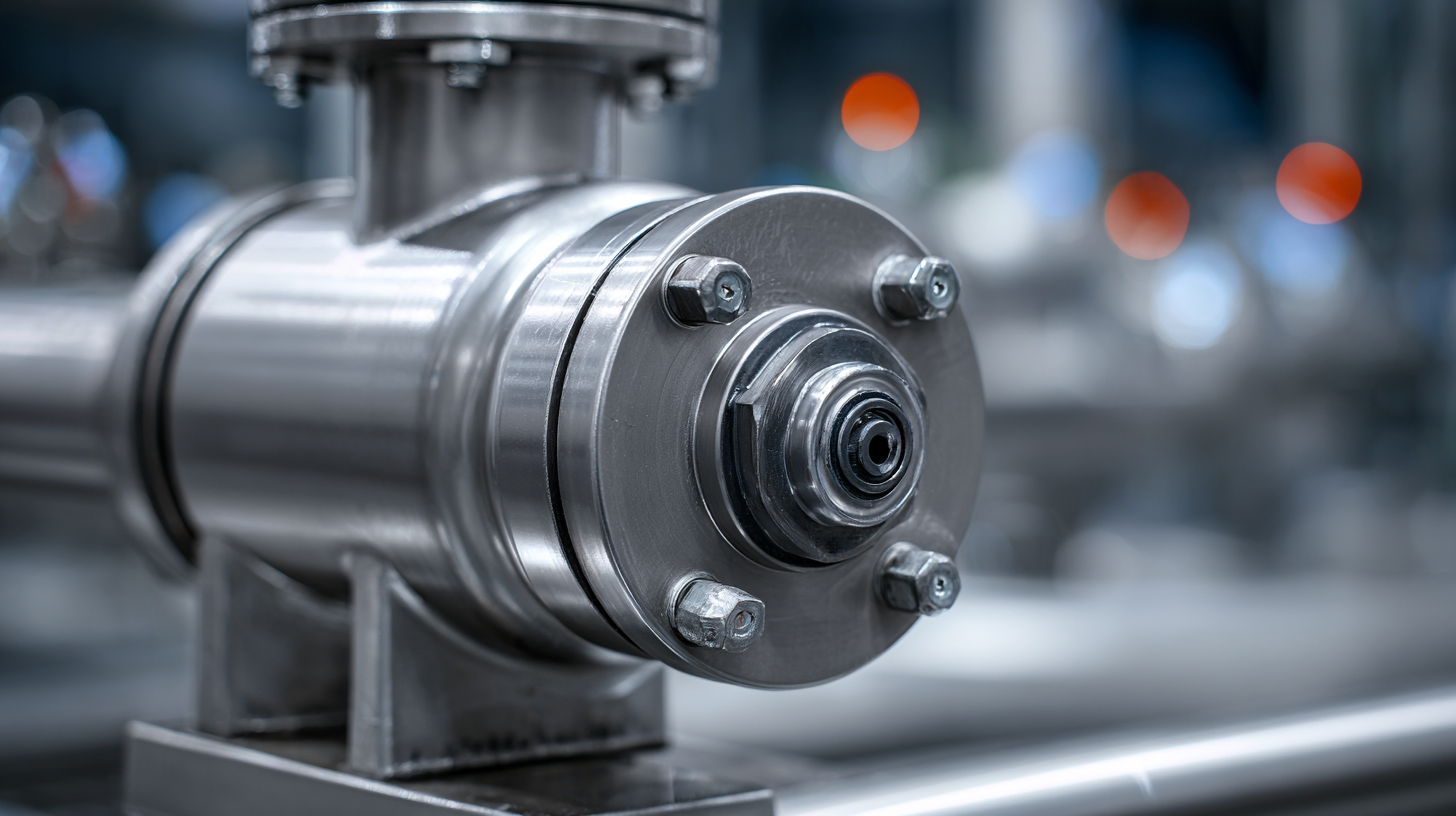

Chemical pumps are essential components in many industrial processes, offering a range of benefits that enhance operational efficiency and safety. One of the primary advantages of utilizing chemical pumps is their ability to handle various corrosive and viscous fluids without compromising integrity. These pumps are designed to withstand harsh conditions and are often constructed from materials resistant to chemical reactions, ensuring longevity and reliability in demanding environments.

Moreover, chemical pumps facilitate precise control over the flow rate of liquids, which is critical in industries such as pharmaceuticals, food and beverage, and chemical manufacturing. This precision not only optimizes production efficiency but also minimizes waste and reduces costs. Additionally, the ability to automate pumping processes reduces manual labor, thereby enhancing workplace safety and allowing for better resource allocation in industrial operations. The implementation of chemical pumps ultimately contributes to improved product quality, adherence to regulatory standards, and a more sustainable production process.

Factors to Consider When Selecting the Right Chemical Pump

When selecting the right chemical pump for your industrial applications, several critical factors must be considered to ensure optimal performance and safety. First and foremost, understanding the chemical properties of the fluids being handled is essential. This includes the viscosity, density, and corrosiveness of the chemicals. Pumps must be compatible with these characteristics to prevent material degradation and ensure efficient fluid transfer.

Additionally, the operating environment plays a significant role in pump selection. Considerations such as temperature fluctuations, pressure requirements, and the potential for external contaminants should inform your choice. It is also vital to evaluate the required flow rates and head conditions to ensure that the pump can meet operational demands. Finally, ease of maintenance and accessibility can affect long-term operational efficiency and downtime. By carefully analyzing these factors, industries can select a chemical pump that maximizes performance, enhances safety, and minimizes repair costs.

Related Posts

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

How to Choose the Right Commercial Pump for Your Business Needs

-

7 Essential Tips for Choosing the Right Chemical Injection Pumps

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

Understanding the Role of Chemical Feed Pumps in Modern Industrial Applications