Blog

How to Choose the Right Commercial Pump for Your Business Needs

Choosing the right commercial pump for your business needs is a critical decision that can significantly impact operational efficiency and cost-effectiveness. According to a recent report by MarketsandMarkets, the global industrial pump market is projected to reach $85 billion by 2025, with commercial pumps accounting for a substantial segment due to their essential roles in various applications such as water treatment, chemical processing, and agriculture. Furthermore, a study conducted by Freedonia Group highlights that the demand for commercial pumps is consistently driven by advancements in technology and a growing awareness of energy-efficient solutions.

Selecting the appropriate commercial pump not only involves understanding the specific requirements of your operations but also evaluating factors such as pump type, flow rate, and materials to ensure longevity and reliability. In today’s competitive market, making an informed choice in commercial pumps is crucial for optimizing performance and minimizing operational costs.

Identifying Your Business's Pump Requirements and Applications

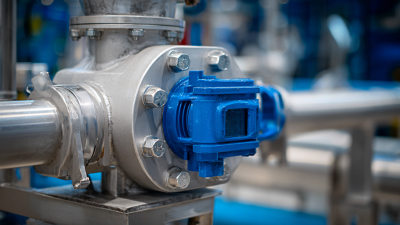

When selecting a commercial pump for your business, the first step is to thoroughly identify your specific requirements and applications. This involves understanding the fluids you will be handling, such as water, chemicals, or viscous materials, as each type has distinct properties that necessitate different pump designs. For instance, if you work with highly corrosive substances, materials like stainless steel or thermoplastics might be essential to ensure durability and safety. Additionally, consider the temperature range and pressure conditions that will affect pump performance, as these factors can significantly influence the efficiency and longevity of your equipment.

Another important aspect to consider is the flow rate and head requirements for your operations. Assess how much fluid you need to move and at what speed, as this will determine the size and type of pump suitable for your needs. Common applications such as irrigation, industrial processes, or wastewater treatment may require specialized pumps designed for higher efficiency and lower maintenance. By thoroughly evaluating these elements, you can ensure that the pump you choose aligns with your operational needs and supports the overall productivity of your business.

How to Choose the Right Commercial Pump for Your Business Needs

| Application | Pump Type | Flow Rate (GPM) | Head Pressure (Feet) | Power Source | Material |

|---|---|---|---|---|---|

| Water Treatment | Submersible Pump | 50 | 30 | Electric | Stainless Steel |

| Irrigation | Centrifugal Pump | 100 | 40 | Diesel | Cast Iron |

| Chemical Processing | Diaphragm Pump | 25 | 20 | Electric | Polypropylene |

| Food & Beverage | Peristaltic Pump | 10 | 15 | Electric | Silicone |

| Construction | Trash Pump | 75 | 35 | Gasoline | Aluminum |

Understanding Different Types of Commercial Pumps Available

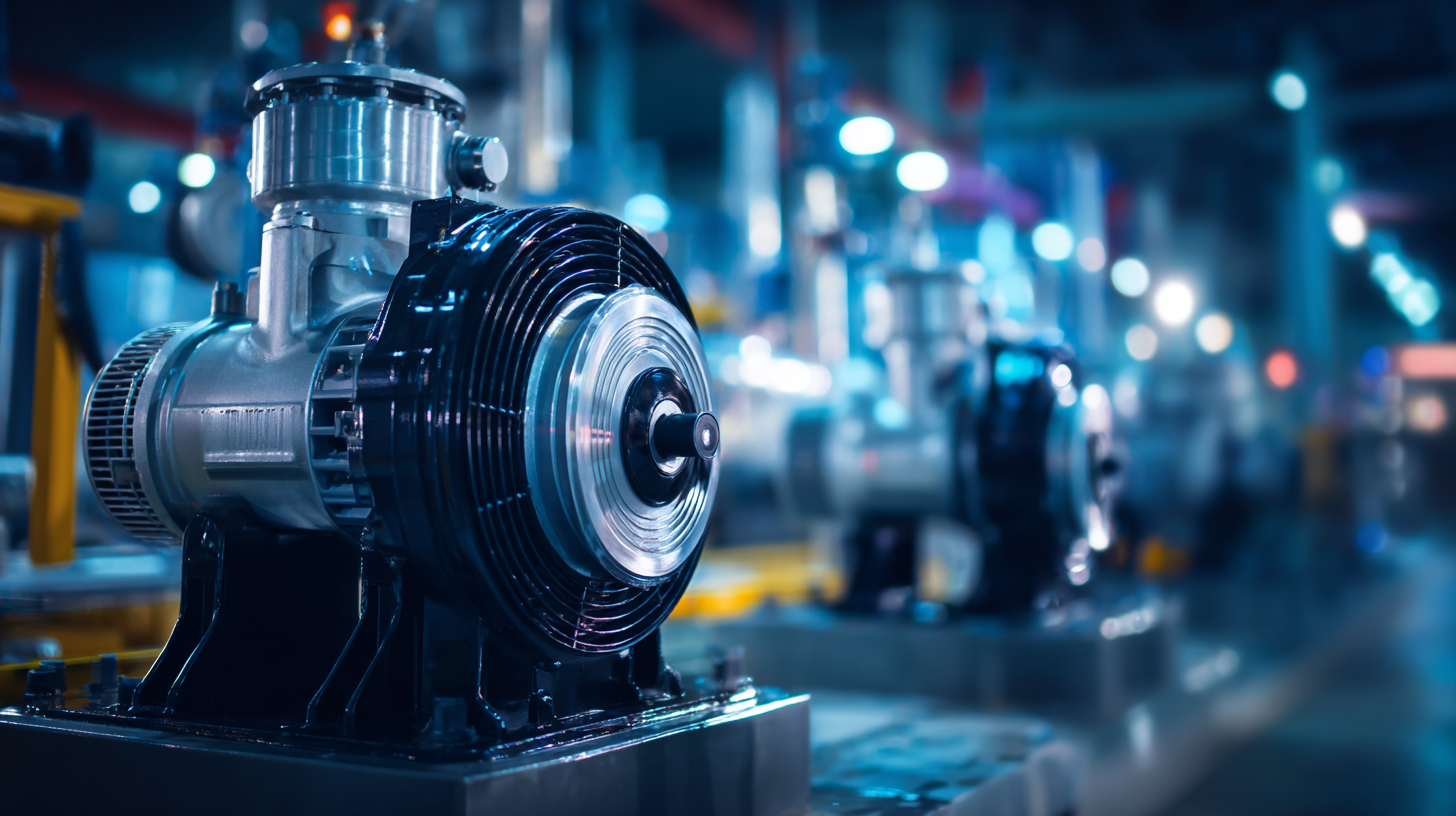

When selecting the right commercial pump for your business needs, understanding the various types available is crucial. Commercial pumps can be broadly categorized into centrifugal pumps, positive displacement pumps, and submersible pumps. According to the Global Industrial Pump Market Report, the centrifugal pump segment dominates the market, accounting for about 48% of the total share in 2022 due to its efficiency in moving large volumes of liquid. These pumps are ideal for applications requiring fluid transfer and circulation in industries such as water treatment and chemical processing.

Positive displacement pumps, while less prevalent, offer unique advantages for specific applications. They excel in scenarios where high viscosity fluids are involved, making them indispensable in the food and beverage, oil and gas, and pharmaceutical industries. The Increasing Demand for Positive Displacement Pumps report notes that these pumps are projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030, driven by the rising need for precise flow control. Additionally, submersible pumps, designed to operate underwater, are essential in waste management and mining, providing effective solutions to fluid extraction from deep sources. Understanding these pump types will help businesses make informed decisions that ensure efficiency and reliability in their operations.

Evaluating Pump Specifications for Optimal Performance

When selecting a commercial pump for your business, evaluating pump specifications is crucial for ensuring optimal performance. Pumps come in various types and sizes, each with specific capabilities suited for different applications. Understanding the required flow rate, pressure, and the fluid’s characteristics will help narrow down your options. It is essential to assess the pump's materials of construction, especially if the fluid being pumped is corrosive or abrasive.

Tips: Always consider the total dynamic head (TDH) when choosing a pump. It represents the height the liquid needs to be lifted and accounts for friction losses in the system. Understanding this will guide you in selecting a pump that minimizes energy consumption and maximizes efficiency.

Additionally, pay attention to the pump’s power requirements and operating conditions. Check for energy efficiency ratings and ensure that the pump operates well within its recommended limits to prevent premature failure. Maintenance accessibility is another vital factor—choose a design that allows easy access for routine checks and repairs to ensure your pump remains reliable over time.

Commercial Pump Performance Analysis

Considering Energy Efficiency and Cost of Ownership

When selecting the right commercial pump for your business, energy efficiency and cost of ownership are pivotal factors that can significantly impact your bottom line. According to a report by the U.S. Department of Energy, pumps can account for about 20% of industrial energy consumption. Therefore, investing in energy-efficient models not only helps reduce energy bills but also contributes to lower greenhouse gas emissions. For instance, centrifugal pumps designed with advanced hydraulic optimization can achieve efficiency ratings of over 90%, which, while initially more expensive, can result in significant savings over the pump's operational lifespan.

Moreover, understanding the total cost of ownership (TCO) is essential when making your decision. A study by the Hydraulic Institute revealed that operational costs, including energy consumption, maintenance, and repair, can represent up to 80% of a pump's TCO over time. By choosing a pump that minimizes both energy consumption and maintenance requirements, businesses can substantially lower their overall expenses. For example, selecting pumps with smart monitoring features can prevent costly downtime by alerting users to potential issues before they escalate, ultimately enhancing productivity and reliability.

Assessing Maintenance and Support Needs for Your Pump System

When selecting the right commercial pump for your business, assessing maintenance and support needs is paramount. A reliable pump system not only enhances operational efficiency but also reduces unexpected downtime, which can be costly. It's essential to evaluate the availability of maintenance services and the expertise of service providers in your area. Engaging with companies that offer a Maintenance Provision Rating Scheme (MPRS) can guide you in making informed decisions, ensuring that you have access to reliable workshops that meet your specific needs.

Additionally, integrating predictive maintenance techniques can significantly enhance the longevity and performance of your pump systems. By utilizing data-driven analysis, businesses can forecast potential issues before they escalate, streamlining maintenance and support efforts. As an example, the newfound focus on solar-powered water pumps highlights the importance of sustainable and efficient solutions in rural areas. These innovative devices not only utilize renewable energy but also require tailored maintenance strategies to ensure their optimal functionality over time.

Related Posts

-

5 Essential Tips for Choosing the Right Commercial Pump for Your Business Needs

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

The Future of Suction Pump Technology Revolutionizing Efficiency and Performance

-

Innovative Tank Mixer Applications Across Various Industries