Blog

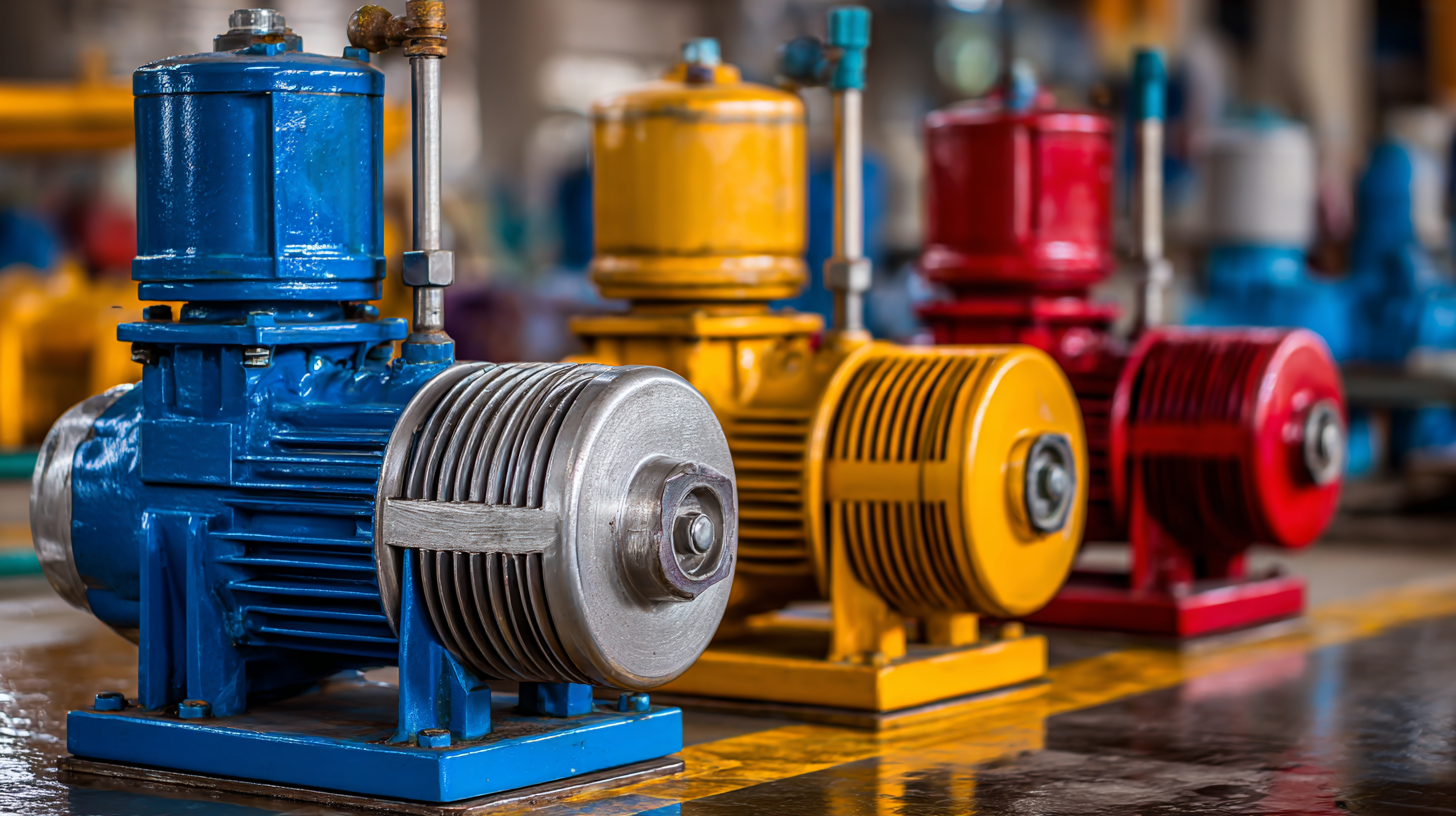

How to Choose the Right Types of Pumps for Your Industrial Needs: A Comprehensive Guide

In the ever-evolving landscape of industrial operations, selecting the right types of pumps is crucial for maximizing efficiency and performance. Expert hydrodynamics engineer Dr. Emily Carter emphasizes, "Understanding the distinct characteristics and applications of various types of pumps is essential for ensuring operational reliability and cost-effectiveness." With numerous options available, ranging from centrifugal pumps to positive displacement pumps, narrowing down the choices based on specific industry needs can be a daunting task.

This comprehensive guide aims to demystify the selection process by providing critical insights into the different types of pumps. As industries continue to grow and innovate, the demand for specialized pumping solutions increases, making it imperative for engineers and decision-makers to have a thorough understanding of the available types of pumps. By examining the key features, advantages, and ideal applications of each type, this guide will equip you with the knowledge necessary to make informed decisions that align with your industrial needs.

Understanding Different Types of Pumps and Their Applications in Industry

When selecting the appropriate pump for industrial needs, it’s essential to understand the different types of pumps and their specific applications within various sectors. There are primarily two broad categories: positive displacement pumps and centrifugal pumps. Positive displacement pumps function by trapping a fixed amount of fluid and forcing it into the discharge pipe, making them ideal for high-viscosity fluids or applications requiring consistent flow rates. On the other hand, centrifugal pumps are suited for applications involving lower-viscosity fluids, utilizing rotational energy to move fluid, which is ideal for processes like cooling or water circulation in many industries.

In sectors like food and beverage, where hygiene and cleanliness are vital, specific pump types such as sanitary centrifugal pumps are designed to meet stringent sanitation standards. The portable air sampling pump market is another area showing significant growth. Depending on the flow rate required, low flow and high flow air sampling pumps are chosen for different applications, highlighting the importance of tailored solutions in industrial settings. Understanding these distinctions helps in making informed decisions that cater to the unique operational needs of each industry.

Key Factors to Consider When Selecting Pumps for Industrial Operations

When selecting pumps for industrial operations, it is essential to consider several key factors to ensure optimal performance and efficiency. One of the primary considerations is the type of pump required for the specific application. There are various pump types available, such as overhung impeller, between bearing, and vertically suspended pumps. Each type has its unique advantages, making it suitable for different tasks, such as handling different flow rates, pressures, and fluid characteristics.

Additionally, understanding the operational conditions, including the fluid properties—such as viscosity, temperature, and chemical compatibility—is crucial in making the right choice. The pump's design should match the system requirements, whether it is dealing with abrasive materials, high-temperature fluids, or corrosive substances. Taking into account energy efficiency and maintenance needs is also vital, as these factors directly impact the long-term operational costs and reliability of the pump in industrial applications.

By carefully evaluating these elements, businesses can select the most appropriate pump type that aligns with their specific needs.

Comparison of Centrifugal vs. Positive Displacement Pumps

When choosing between centrifugal and positive displacement pumps for industrial applications, it’s essential to understand the fundamental differences and operational characteristics of each type. Centrifugal pumps, known for their ability to handle large volumes of liquid, work best with low-viscosity fluids. They operate based on the principle of centrifugal force, making them ideal for applications requiring steady flow rates. However, they can struggle with variations in pressure or viscosity. On the other hand, positive displacement pumps are more versatile when dealing with high-viscosity fluids and can maintain consistent flow regardless of pressure changes.

**Tips:** When selecting a pump, consider the fluid's properties, including viscosity and temperature, as well as the desired flow rate and pressure. Additionally, assess the specific application requirements, such as whether the pump will be continuously in use or if it needs to handle varied materials.

Recent studies highlight the growing market for sanitary pumps, particularly single-use options that enhance the efficiency of new biologic drug development. Technologies such as diaphragm pumps are gaining traction, offering benefits in hygienic processing. Keep an eye on advancements like twin-screw pumps, which are being explored for their capabilities in both positive displacement and as energy recovery systems in reverse mode, showcasing the evolving landscape of pump technology.

How to Choose the Right Types of Pumps for Your Industrial Needs: A Comprehensive Guide - Comparison of Centrifugal vs. Positive Displacement Pumps

| Feature | Centrifugal Pumps | Positive Displacement Pumps |

|---|---|---|

| Mechanism | Utilizes rotational energy to move fluid | Displaces a fixed amount of fluid with each cycle |

| Efficiency | High efficiency at designed flow rates | Generally lower efficiency; more suitable for viscous fluids |

| Typical Applications | Water supply, chemical processing, wastewater management | Food processing, oil extraction, chemical dosing |

| Pressure Handling | Can handle high flow rates but limited pressure | Excellent for high pressure, low flow applications |

| Maintenance | Lower maintenance requirements, simpler design | Higher maintenance due to complexity and wear issues |

| Fluid Types | Best for thin, non-viscous fluids | Handles viscous fluids and slurries effectively |

Maintenance Tips for Ensuring Optimal Pump Performance in Industrial Settings

Maintaining optimal pump performance is crucial in industrial settings to ensure efficient operation and prolong the lifespan of your equipment. Regular inspections should be a primary focus; this includes checking for leaks, unusual vibrations, or noises that may indicate underlying issues. Additionally, monitoring fluid levels and temperatures can help identify potential problems before they escalate, allowing for timely maintenance actions.

Another vital aspect of maintenance is ensuring that all components, such as seals and bearings, are in good condition. Routine lubrication of moving parts is essential to reduce friction and wear. It's also important to clean filters and strainers regularly to prevent clogging, which can lead to decreased pump efficiency. Proper record-keeping of maintenance activities can aid in tracking pump performance over time and help in scheduling preventive maintenance, ultimately ensuring your pumps operate at peak efficiency.

Future Trends in Pump Technology and Their Impact on Industrial Needs

As the industrial sector continues to evolve, the demand for innovative pump technology is growing. According to market forecasts, the global hydraulic pump market is expected to expand from $1.0759 billion in 2025 to $1.46611 billion by 2033, with a compound annual growth rate (CAGR) of 4.8%. This growth highlights the increasing reliance on advanced fluid management systems in various applications, including mining, metallurgy, and wastewater treatment.

One notable trend appears in the positive displacement pump sector, projected to grow significantly. The market size is anticipated to surge from $69 billion in 2019 to a staggering $157.2 billion by 2032, showcasing a robust CAGR of 6.91%. This growth is driven by technological advancements that enhance efficiency and reliability, essential for meeting the increasing demands of global industrialization and manufacturing. Furthermore, sectors like the high-pressure plunger pump market are also on an upward trajectory, with expectations to grow steadily from $159.04 million in 2025 to $121.72 million by 2033, reflecting a 3.4% CAGR.

These projections suggest that the future of pump technology will not only influence efficiency and operational capabilities in industries but also reshape how companies approach energy management and resource utilization. As manufacturers continue to innovate and improve pump designs, industries will benefit from greater performance, thus aligning with their growing operational needs.

Related Posts

-

Understanding the Role of Industrial Metering Pumps in Modern Manufacturing Processes

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

Harnessing Innovation in Pump Accessories at the 138th Canton Fair 2025 with Market Insights Driving Growth