Blog

Understanding the Mechanics of Diaphragm Pumps: The Key to Efficient Fluid Transfer

Diaphragm pumps are increasingly recognized as vital components in fluid transfer applications across various industries, including chemical processing, wastewater treatment, and food production. According to a recent market analysis by Research and Markets, the global diaphragm pump market is projected to grow at a CAGR of 6.3% over the next five years, driven by their advantages such as dry-running capabilities, self-priming features, and the ability to handle viscous fluids. Understanding the mechanics of diaphragm pumps is crucial to optimizing their performance and efficiency. By examining their operating principles and various design configurations, industries can effectively enhance their fluid transfer processes while reducing operational costs. This comprehensive exploration aims to provide essential insights and practical tips for maximizing the effectiveness of diaphragm pumps, ensuring they meet the evolving demands of fluid management.

Diaphragm pumps are increasingly recognized as vital components in fluid transfer applications across various industries, including chemical processing, wastewater treatment, and food production. According to a recent market analysis by Research and Markets, the global diaphragm pump market is projected to grow at a CAGR of 6.3% over the next five years, driven by their advantages such as dry-running capabilities, self-priming features, and the ability to handle viscous fluids. Understanding the mechanics of diaphragm pumps is crucial to optimizing their performance and efficiency. By examining their operating principles and various design configurations, industries can effectively enhance their fluid transfer processes while reducing operational costs. This comprehensive exploration aims to provide essential insights and practical tips for maximizing the effectiveness of diaphragm pumps, ensuring they meet the evolving demands of fluid management.

Key Components of Diaphragm Pumps That Influence Performance

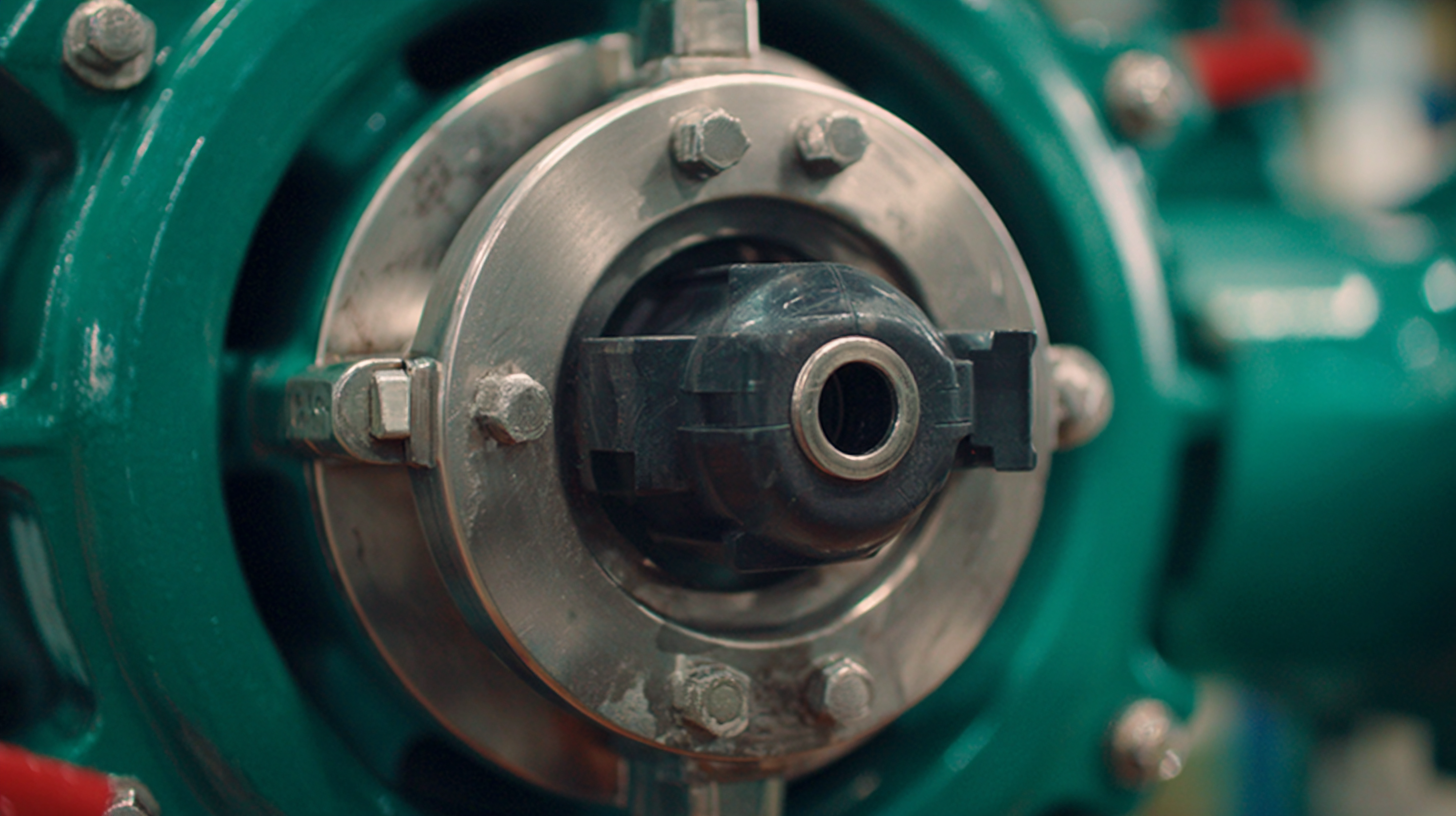

Diaphragm pumps are essential for transferring various fluids efficiently, and understanding their key components can significantly enhance performance. The primary parts include the diaphragm itself, check valves, and the pump body. The diaphragm acts as the heart of the pump, enabling the movement of fluid with each cycle. Materials used for the diaphragm, such as rubber or Teflon, can influence chemical resistance and durability. Choosing the right material based on the application is crucial for optimal performance.

Check valves in diaphragm pumps ensure one-way fluid flow, preventing backflow and maintaining pressure. The design and quality of these valves can greatly affect the pump's efficiency and responsiveness. Regular maintenance and inspection of these components can help identify wear and tear, leading to timely replacements and less downtime.

**Tips:** Always consider the specific fluid characteristics before selecting a diaphragm pump to ensure compatibility with the materials used. Additionally, a routine check-up schedule for the diaphragm and check valves can prevent major issues and prolong the lifespan of the pump. Engaging with a supplier knowledgeable about your application will help you make informed decisions about these components.

Understanding the Mechanics of Diaphragm Pumps: The Key to Efficient Fluid Transfer

| Component | Description | Effect on Performance |

|---|---|---|

| Diaphragm Material | Materials like rubber, neoprene, or PTFE that form the pump's diaphragm. | Affects chemical compatibility, flexibility, and longevity under pressure. |

| Valve Design | Includes ball or flap valves that control the flow of fluid. | Influences flow rate and efficiency of fluid transfer. |

| Pump Size | The overall dimensions and inlet/outlet sizes of the pump. | Determines the flow capacity and applications suitability. |

| Drive Mechanism | Mechanism such as electric motor or pneumatic drive that powers the pump. | Impacts speed, efficiency, and operational costs. |

| Pressure Range | The operational pressure limits within which the pump performs effectively. | Influences the range of fluids that can be transferred without leakage. |

Understanding Different Types of Diaphragm Pumps for Fluid Transfer

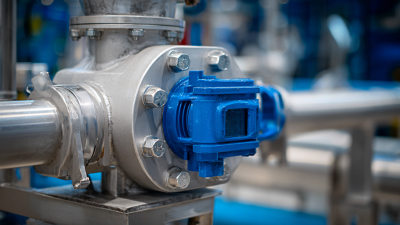

Diaphragm pumps are essential tools for efficient fluid transfer across various industries, and understanding the different types available can significantly enhance their application. There are primarily two classifications of diaphragm pumps: air-operated and electric diaphragm pumps. Air-operated diaphragm pumps utilize compressed air to create a suction effect, making them highly versatile for handling abrasive and viscous fluids. Their ability to run dry and self-prime is a notable advantage, providing reliability in various working conditions.

On the other hand, electric diaphragm pumps are powered by electric motors, offering precise control over fluid flow rates and pressure. These pumps are often preferred in applications requiring a constant transfer speed and a cleaner operation, reducing the risks associated with air contamination. Moreover, they are commonly used in laboratories and precise dosing applications. Each type of diaphragm pump presents unique benefits, and choosing the right one depends on specific operational needs, including the nature of the fluid being transferred and the environmental conditions of the application.

Tips for Selecting the Right Diaphragm Pump for Your Application

When selecting the right diaphragm pump for your application, it’s crucial to consider the specific needs of your fluid transfer requirements. First, assess the properties of the fluid you’ll be pumping—such as viscosity, corrosiveness, and temperature. Diaphragm pumps excel with a variety of fluids but may require specific materials for the diaphragm and pump body to prevent wear and damage. For example, if you're working with abrasive or corrosive fluids, selecting pumps with Teflon or rubber diaphragms can enhance durability and functionality.

Another important factor is the pump's flow rate and pressure capabilities. Diaphragm pumps are available in various sizes and designs, allowing for customization to meet the demands of your application. Consider the required flow rate, whether intermittent or continuous, and match it with the pump’s specifications. Additionally, ensure that the pump’s operating pressure aligns with your system requirements. By carefully evaluating these aspects, you can select a diaphragm pump that optimizes performance and reliability in your fluid transfer operations.

Common Challenges in Diaphragm Pump Operation and Their Solutions

In the realm of fluid transfer, diaphragm pumps are essential due to their versatility and reliability. However, operators often encounter a range of challenges that can impede their performance. Common issues include air leakage, improper diaphragm material selection, and difficulties in achieving the desired flow rate. Addressing these challenges is crucial for enhancing operational efficiency and ensuring uninterrupted service.

For instance, the Electric Operated Double Diaphragm (EODD) pumps are projected to witness significant growth, with a market CAGR of 8.9% and a valuation anticipated to reach $941.1 million by 2034. Innovations in pump technology, such as advancements in motor efficiency and materials, play a pivotal role in overcoming operational hurdles. Moreover, the recent enhancements in electric double diaphragm pumps, which now feature improved input power efficiency and torque capabilities, demonstrate a proactive approach to resolving industry-specific challenges. Adapting to these improvements can substantially reduce downtime and operational costs for users.

Maintenance Practices to Enhance Diaphragm Pump Efficiency

To enhance diaphragm pump efficiency, regular maintenance practices are crucial. According to a report by the Hydraulic Institute, pumps generally account for 20-25% of a facility's energy consumption. Neglecting maintenance can lead to significant performance losses, with efficiency drops of up to 15% over time. Routine inspections should focus on checking for wear and tear on diaphragms, as degraded components can cause leaks and reduced flow rates, further elevating operational costs.

Additionally, fluid compatibility is essential in diaphragm pump maintenance. A study published in the Journal of Hydraulic Engineering indicates that using incompatible fluids can result in rapid deterioration of the pump materials, leading to unexpected downtime. Periodic flushing and proper cleaning procedures can prevent the buildup of debris, ensuring that pumps operate smoothly and efficiently. Implementing a predictive maintenance strategy, backed by data analytics, can help identify potential failures before they occur, maximizing the lifespan and efficiency of diaphragm pumps.

Related Posts

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control

-

Understanding the Benefits of Chemical Metering Pumps in Modern Water Treatment Systems