Blog

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

In today's dynamic industrial landscape, selecting the right equipment is crucial for optimizing processes and ensuring precision in various applications. Among the essential tools in the realm of fluid management, the chemical metering pump stands out for its critical role in accurately delivering precise quantities of chemicals. As global buyers increasingly seek efficient and reliable solutions, understanding the key features that define the best chemical metering pumps becomes paramount. This blog will delve into seven essential features that not only enhance performance but also contribute to safety and cost-effectiveness. By exploring these characteristics, buyers can make informed decisions, ensuring they invest in a chemical metering pump that meets their specific needs and aligns with industry standards.

Join us as we uncover the must-have attributes that can elevate operational efficiency and reliability in chemical dosing applications.

Key Considerations for Selecting the Right Chemical Metering Pump

When selecting the right chemical metering pump, several key considerations come into play to ensure optimal performance and compatibility with your application. First, it’s crucial to assess the pump's capacity and flow rate. Understanding the specific requirements of your operation will help you choose a pump that can handle the required chemical volume efficiently. Additionally, take into account the viscosity and chemical composition of the liquids being pumped. Some materials may require specialized pump designs or constructions to prevent corrosion and ensure longevity.

Another important aspect is the pump's accuracy and reliability. Look for models that offer precise flow measurement and control to maintain desired chemical concentrations. Variable-speed settings and advanced control options can significantly enhance performance, particularly in dynamic processes. Furthermore, consider the design and ease of maintenance. A pump that allows for quick disassembly and service can save time and reduce downtime in critical applications. By carefully evaluating these factors, global buyers can make informed decisions that align with their operational needs and ensure the longevity and effectiveness of their chemical metering systems.

Understanding Different Types of Chemical Metering Pumps and Their Applications

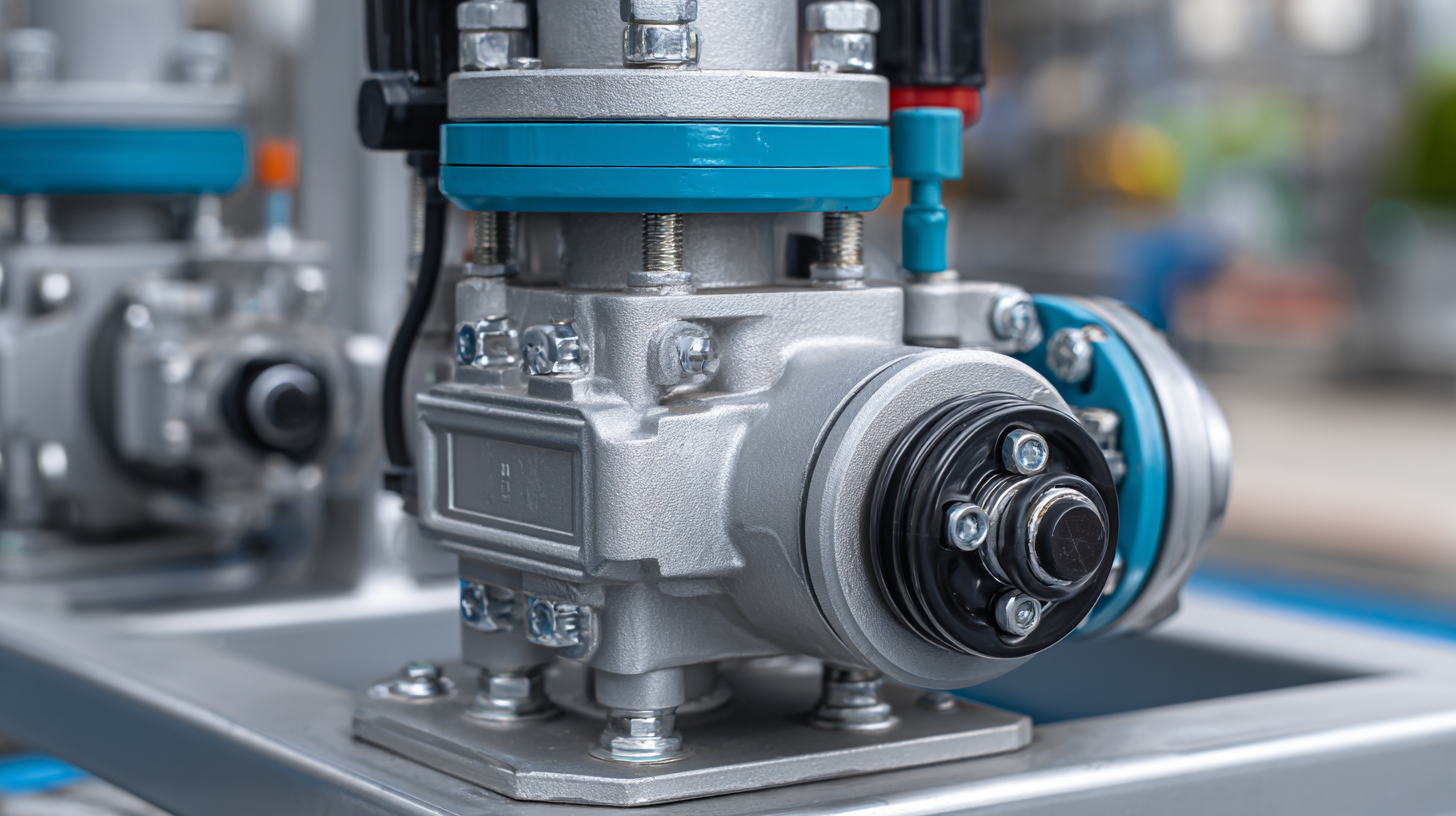

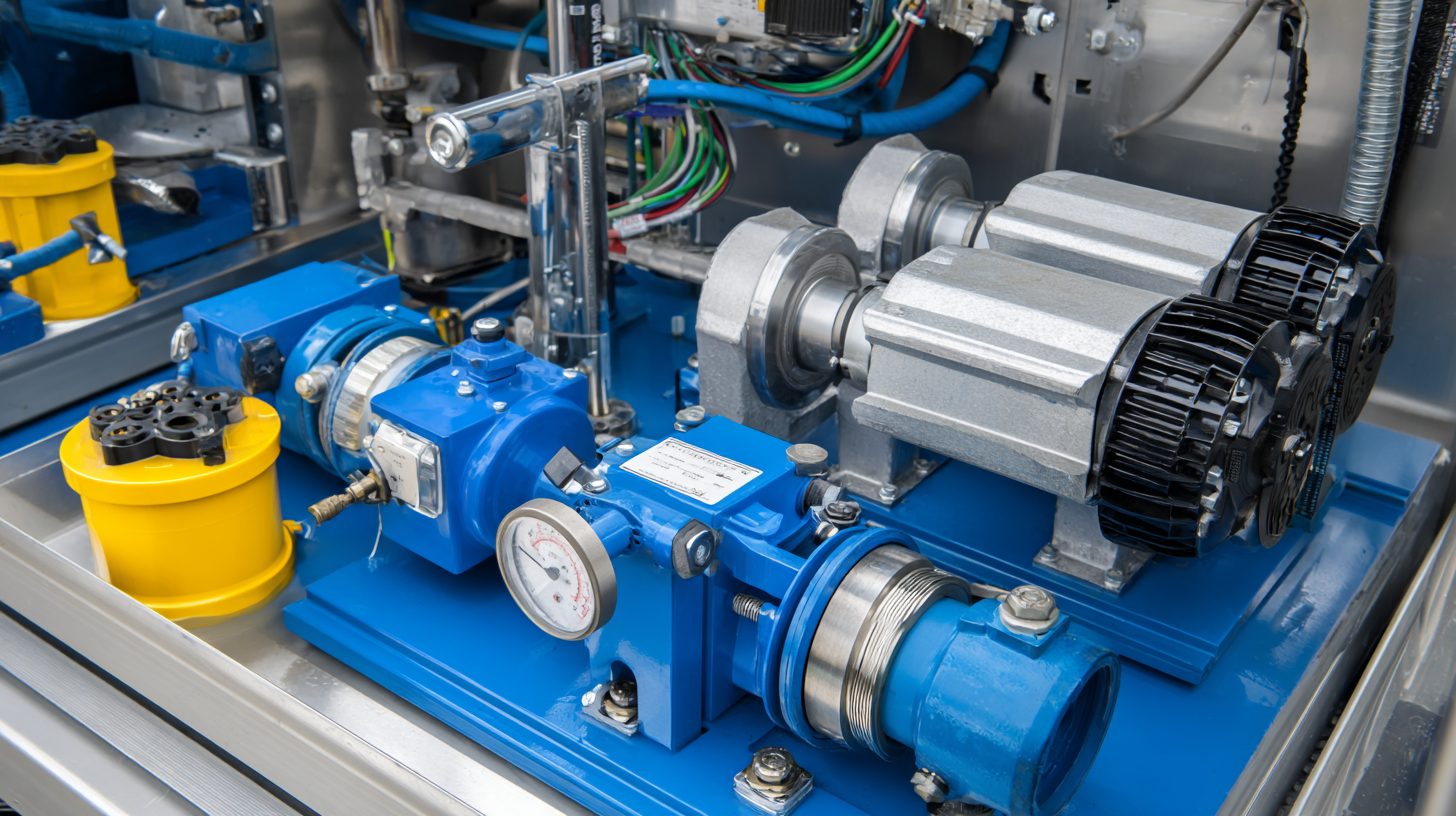

Chemical metering pumps play a crucial role in various industries, ensuring precise and controlled chemical dosing for applications ranging from water treatment to food processing. Understanding the different types of chemical metering pumps is essential for global buyers looking to optimize their operations. The most common types include diaphragm pumps, gear pumps, and peristaltic pumps, each designed to suit specific chemical types and delivery requirements.

Diaphragm pumps are widely recognized for their ability to handle corrosive substances while maintaining accuracy in low and high-pressure settings. Gear pumps, on the other hand, are ideal for high-viscosity chemicals, providing smooth flow and consistent output. Peristaltic pumps are often used for applications where sanitary conditions are paramount, as they allow for the safe transport of sensitive liquids without contamination. By grasping these distinctions and their respective applications, buyers can make informed decisions when selecting the best chemical metering pumps for their particular needs.

Essential Features Enhancing Precision and Reliability in Metering Pumps

When selecting a chemical metering pump, precision and reliability are paramount for global buyers. These pumps play a crucial role in various industries, where accurate dosing of chemicals is essential for operational safety and efficiency. One of the key features enhancing precision is adjustable stroke length. This capability allows operators to customize the output based on specific process requirements, ensuring that each injection accurately meets the desired concentration levels.

In addition to adjustable stroke lengths, the best metering pumps are also equipped with advanced controls that facilitate real-time monitoring and feedback. These features ensure that any deviations from the set parameters can be promptly addressed, enhancing overall operational reliability. Moreover, materials used in pump construction should be resistant to the chemicals being handled. This not only prevents contamination but also extends the lifespan of the pump, thus reducing the long-term costs for buyers. Overall, the integration of these essential features leads to improved process control, safety, and efficiency, making these pumps indispensable in numerous applications across the globe.

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

| Feature | Description | Importance | Application |

|---|---|---|---|

| Flow Rate Control | Ability to accurately adjust the flow rate as needed. | Ensures precise chemical dosage and process consistency. | Chemical processing, wastewater treatment. |

| Material Compatibility | Constructed from materials that resist corrosion and chemical degradation. | Increases the lifespan and reliability of the pump. | Pharmaceuticals, food industry, petrochemicals. |

| Self-Priming Capability | Can prime itself without external assistance, maintaining operational efficiency. | Prevents downtime and promotes uninterrupted service. | Water treatment, agricultural applications. |

| Pulsation Dampening | Mitigates pressure fluctuations for smoother operation. | Enhances consistency in dosing and process performance. | Chemical feed systems, industrial processes. |

| Integrated Control Systems | Features advanced control options for better monitoring and automation. | Facilitates remote operation and reduces labor costs. | Manufacturing, process optimization. |

| Safety Features | Includes automatic shut-off, leak detection, and alarms. | Protects personnel and the environment from hazardous chemicals. | Chemical manufacturing, hazardous waste management. |

| Ease of Maintenance | Designed for straightforward maintenance and service. | Reduces downtime and service costs. | Any chemical handling system. |

The Importance of Materials and Construction in Chemical Pump Durability

When selecting chemical metering pumps, the importance of materials and construction cannot be overstated. The durability of a pump largely depends on the quality of materials used in its manufacturing. High-performance pumps typically incorporate corrosion-resistant materials such as PVC, PVDF, and stainless steel, which can withstand aggressive chemical environments. This resistance not only prolongs the lifespan of the pump but also ensures reliable operation under varying pressure and temperature conditions. Buyers must prioritize pumps that feature advanced polymers and coatings that provide an additional layer of protection against chemical wear.

In addition to material selection, the construction of the pump plays a critical role in its overall durability. A well-designed pump will have features such as reinforced housings and precision-engineered components that minimize wear and tear during operation. Furthermore, pumps with a modular design allow for easier maintenance and replacement of parts, which supports long-term use and efficiency. Investing in a pump with a solid construction and high-quality materials can significantly reduce downtime and operational costs, making it essential for global buyers to consider these factors when making their selection.

Cost-Effectiveness: Balancing Price and Performance in Metering Pump Choices

When selecting a chemical metering pump, cost-effectiveness is a crucial factor that every global buyer must consider. It is essential to strike a balance between price and performance to ensure that you are making a wise investment. While it may be tempting to choose the cheapest option available, it is important to assess whether that choice meets your operational requirements and offers long-term reliability. High-quality pumps may come with a higher initial price, but their enhanced durability and efficiency can ultimately lead to lower total operating costs.

Tip: Always conduct a life-cycle cost analysis to evaluate the true cost of ownership, which includes maintenance, energy consumption, and potential downtime. This approach will help you to make a more informed decision that aligns with your budget and operational needs.

Another critical factor in the cost-effectiveness of metering pumps is the availability of service and support. Pumps that come with strong technical support and spare parts availability often save buyers from unexpected expenses and downtime. Choosing a reputable manufacturer can help ensure you receive ongoing support, which contributes to the overall cost-effectiveness of the purchase.

Tip: Prioritize suppliers that offer comprehensive warranties and robust after-sales service. This guarantees not only your initial investment but also peace of mind regarding maintenance and repairs over the pump’s lifespan.

Cost-Effectiveness: Balancing Price and Performance in Metering Pump Choices

Related Posts

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs

-

Innovative Applications of Diaphragm Pumps Across Various Industries