Blog

7 Essential Tips for Choosing the Right Chemical Injection Pumps

Choosing the right chemical injection pumps is crucial for optimizing industrial processes and ensuring the safe transport and delivery of chemicals. With various types of pumps available, each designed for specific applications and conditions, the selection process can be overwhelming. Factors such as flow rate, pressure, chemical compatibility, and maintenance requirements all play pivotal roles in determining the most suitable pump for your needs. In this article, we will provide you with seven essential tips for selecting the right chemical injection pumps, helping you make informed decisions that enhance operational efficiency and minimize risk. By understanding the fundamental aspects of these pumps, from their operational principles to the latest technologies, you can achieve better performance and reliability in your chemical handling processes.

Understand Your Application Requirements for Chemical Injection Pumps

When selecting the right chemical injection pumps, it is crucial to thoroughly understand your application requirements. Each production system presents unique challenges and conditions that necessitate tailored solutions for chemical injection. For instance, the dynamic nature of production systems means that they experience constant variations, which can affect optimal chemical injection rates. Therefore, identifying the specific chemicals needed, their required injection rates, and the environmental conditions will help ensure the selected pump can deliver consistent performance.

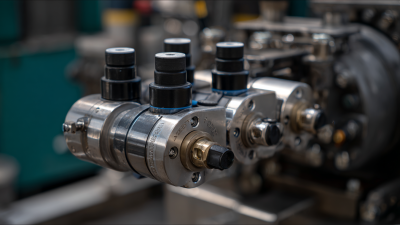

Recent advancements in pump technology, such as solar-powered diaphragm metering, highlight the importance of precision in chemical injection systems. These innovations can significantly enhance operational efficiency and cost-effectiveness in oilfields, allowing for accurate chemical dosing that keeps equipment functioning optimally. Additionally, understanding the need for features that address corrosion and other challenges in varied reservoir conditions will inform better decision-making when selecting a chemical injection pump, ultimately leading to improved profitability in production operations.

Evaluate the Pump Type: Diaphragm vs. Peristaltic for Optimal Performance

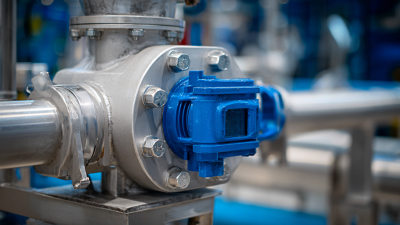

When selecting a chemical injection pump, understanding the differences between diaphragm and peristaltic pumps is crucial for achieving optimal performance in your application. Diaphragm pumps are known for their ability to handle a wide range of viscosities and pressures, making them suitable for transferring corrosive or abrasive fluids. They work by using a flexible diaphragm that creates vacuum pressure to draw fluid into the chamber, ensuring precise dosing with minimal leakage. This design is particularly advantageous in scenarios that demand high accuracy, such as laboratories or chemical processing.

On the other hand, peristaltic pumps are ideal for applications requiring gentle handling of shear-sensitive fluids. These pumps operate by compressing and relaxing a flexible hose, which pushes the fluid through without contaminating it. Their simplistic design allows for easy maintenance and cleaning, making them a preferred choice in food processing, pharmaceuticals, and biotechnology. Furthermore, peristaltic pumps typically handle high solids content fluids effectively, further enhancing their appeal. When deciding between these two types, consider factors such as fluid characteristics, accuracy requirements, and ease of maintenance to choose the pump that best suits your specific needs.

Consider Flow Rate and Pressure Needs for Accurate Chemical Dispensing

When selecting chemical injection pumps, understanding your flow rate and pressure requirements is crucial for effective and accurate chemical dispensing. According to a report by the Chemical Engineering Association, roughly 30% of chemical dosing issues arise from improper pump specifications, leading to under-dosing or over-dosing. Therefore, it's essential to evaluate the specific flow rates required for your application. For instance, if your process requires a flow rate of 5 gallons per hour (GPH) to ensure optimal chemical concentration, a pump that can consistently deliver at that rate will maintain the desired performance and safety standards.

Pressure is another critical factor in pump selection. The pressure needs of your system can significantly impact the efficiency of chemical injection. The Hydraulic Institute indicates that operating pressures often range between 20 to 200 psi depending on the application, and using pumps that can withstand these pressures helps prevent system failures and material degradation. Accurate pressure management, coupled with the right flow rate, ensures that chemicals are delivered more precisely, enhancing both safety and operational efficiency. Thus, detailed calculations and assessments before purchasing your chemical injection pump can save time, money, and resources in the long run.

Flow Rate and Pressure Needs for Chemical Injection Pumps

Assess Material Compatibility to Prevent Corrosion and Pump Failure

When selecting chemical injection pumps, one of the most crucial factors to consider is material compatibility. The wrong choice of materials can lead to severe corrosion and pump failure, which not only disrupts operations but can also result in costly repairs and downtime. Different chemicals have unique properties that may react adversely with certain materials. Therefore, a thorough assessment of the chemicals being pumped is essential.

To assess material compatibility, start by analyzing the chemical composition and potential interactions with various pump materials. Common materials such as stainless steel, PVC, and various elastomers each have their advantages and limitations when exposed to specific chemicals. Additionally, it is essential to consider not only the primary chemical being injected but also any potential contaminants or by-products that may occur during the process. By ensuring that the materials used in the pump are resistant to corrosion and compatible with the chemicals, you can significantly enhance the longevity and reliability of the pump, safeguarding your operations against unforeseen failures.

Review Maintenance and Support Options to Ensure Long-term Reliability

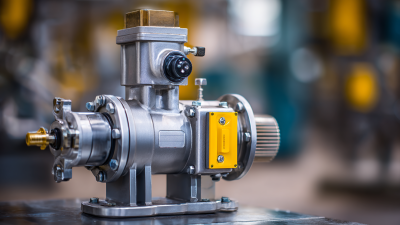

When selecting a chemical injection pump, maintenance and support options should be high on your list of priorities. Reliable maintenance practices are essential for ensuring the long-term efficiency and performance of the pump. Regular inspections and timely replacement of worn-out parts can prevent costly breakdowns and extend the lifespan of the equipment. Additionally, it’s crucial to choose a pump from a manufacturer that offers comprehensive maintenance plans tailored to your operational needs.

Equally important is the availability of support services. A knowledgeable support team can assist you in troubleshooting issues that arise, guiding you through proper operational procedures, and helping integrate the pump seamlessly into your existing system. Before finalizing your choice, consider the company's reputation for customer service and the accessibility of technical support. An ideal vendor should offer training resources and prompt assistance to ensure your operations run smoothly, enabling you to maintain your chemical injection processes effectively.

Related Posts

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

How to Select the Right Injection Pumps for Your Industrial Needs

-

Innovative Tank Mixer Applications Across Various Industries

-

10 Unique Metering Pump Types You Should Know About

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs