Blog

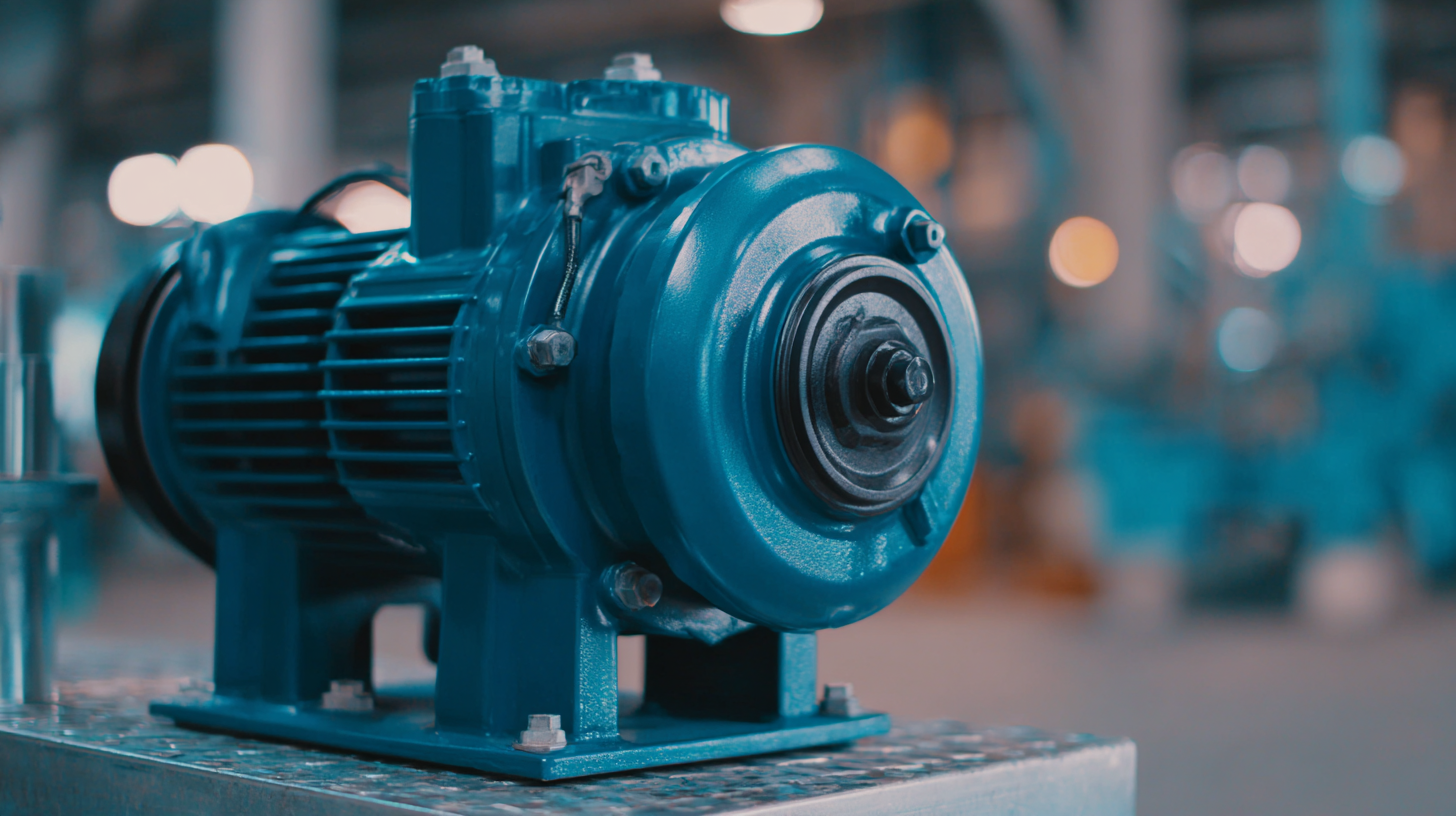

5 Essential Tips for Choosing the Right Commercial Pump for Your Business Needs

Choosing the right commercial pump for your business needs is a critical decision that can significantly impact your operations. With a myriad of options available in the market, understanding the specific requirements of your industry is crucial. Commercial pumps play a vital role in various applications, from water transfer and sewage management to chemical processing and irrigation systems. This guide will provide you with five essential tips to navigate the selection process effectively, ensuring that you invest in equipment that not only meets your operational demands but also promotes efficiency and longevity. By considering factors such as pump type, capacity, material, and maintenance requirements, you can make an informed choice that aligns with your business goals. Whether you're upgrading existing equipment or investing in pumps for the first time, these insights will help streamline your purchasing journey and enhance your operational performance.

Factors to Consider When Assessing Pump Capacity for Your Business

When choosing a commercial pump for your business needs, it is vital to assess the pump capacity accurately. According to recent studies, the selection of pump capacity can significantly impact operational efficiency and cost-effectiveness. For instance, a lifecycle assessment of heat pumps indicates that optimizing capacity can lead to reductions in energy consumption and lower greenhouse gas emissions, crucial for companies aiming to meet sustainability targets.

Additionally, evaluating the specific requirements of your operations is essential. The integration of advanced energy storage technologies has revealed that a well-chosen pump system can bolster overall energy management and compatibility with renewable energy sources. Reports highlight that industrial heat pumps, for example, can decarbonize operations while being tailored to meet varying load demands. By carefully analyzing these factors, businesses can make informed decisions that not only enhance productivity but also align with environmental goals, making it a critical aspect of pump capacity assessment.

Understanding Different Types of Commercial Pumps and Their Applications

When selecting the right commercial pump, understanding the different types and their applications is crucial to meeting your business needs. Commercial pumps come in various designs, each suited for specific applications such as water transfer, chemical processing, or wastewater management. For instance, Centrifugal pumps are commonly used in clean water applications due to their efficiency in transporting fluids at high flow rates. According to recent industry reports, the global centrifugal pump market is projected to grow at a CAGR of 3.9% over the next five years, highlighting their significance in various sectors.

In addition, advancements in pump technologies, such as the introduction of compliant pumps that meet EN733 standards, are revolutionizing municipal water management. These pumps not only enhance operational efficiency but also contribute to sustainability efforts by reducing energy consumption. Furthermore, with the growing focus on decarbonization, industrial heat pumps are gaining traction, as they can significantly reduce greenhouse gas emissions. As industries adapt, selecting the right commercial pump becomes even more critical to ensure compatibility with innovative systems that promote energy efficiency and environmental responsibility.

Evaluating Energy Efficiency and Operational Costs for Pump Selection

When choosing the right commercial pump for your business, energy efficiency and operational costs are paramount considerations. According to a recent trend report, the global market for household water pumps is projected to reach $18.58 billion by 2024, soaring to $26.92 billion by 2032, with a growth rate of 4.8%. This highlights the increasing emphasis on high-efficiency pumps that not only meet energy regulations but also significantly reduce operational expenses.

Tip 1: Assess the energy rating of potential pumps. Higher energy efficiency ratings can lead to substantial cost savings over time, especially in large-scale operations where energy use is a significant expense. A small increase in efficiency can translate to thousands of dollars saved annually.

Tip 2: Consider future operational costs, not just the initial investment. The global hot water recirculating pump market is expected to grow from $8.21 billion in 2024 to $10.79 billion by 2032. Investing in pumps that are not only energy-efficient but also have lower maintenance requirements can mitigate long-term costs and enhance overall reliability.

By carefully evaluating these factors, businesses can make informed decisions that align with both immediate needs and long-term sustainability goals.

Energy Efficiency and Operational Costs of Commercial Pumps

This chart illustrates the energy efficiency and operational costs associated with different types of commercial pumps. Selecting a pump with optimal efficiency can significantly reduce operational costs over time.

Maintenance Requirements: Choosing a Pump That Fits Your Resources

When selecting a commercial pump for your business, it is crucial to evaluate the maintenance requirements, as they can significantly affect both operational efficiency and long-term costs. According to industry reports, maintenance-related issues can account for up to 40% of pump failures. Therefore, choosing a pump that aligns with your available resources for maintenance is essential. For instance, consider pumps designed with easily accessible components that support quick service and reduce downtime.

Another vital factor to consider is the energy efficiency of the pump. Research indicates that optimizing pump operation can save businesses up to 30% on energy costs, contributing to a healthier bottom line. Pumps with advanced monitoring technologies can alert operators when maintenance is necessary, helping to prevent unexpected failures and prolonging the lifespan of the equipment. In a sector increasingly focused on sustainability, selecting a pump that minimizes energy consumption while meeting your operational needs is not only prudent but advantageous for future growth in your business.

The Importance of Supplier Reputation and Customer Support in Pump Selection

When selecting a commercial pump, one of the most critical factors to consider is the reputation of the supplier. A reliable supplier not only offers quality products but also demonstrates integrity and consistency in their business practices. Before finalizing your choice, research the supplier's background, customer reviews, and industry standing. A well-regarded supplier is more likely to provide a pump that meets your operational requirements and withstands the test of time.

Another crucial aspect is customer support. The complexities of pump systems often necessitate professional advice and assistance, making robust customer support indispensable. Opt for suppliers that offer comprehensive support services, which include installation guidance, maintenance checks, and troubleshooting assistance. This not only ensures smooth operation but can also prevent costly downtimes. Always inquire about the availability of technical support and the response time, as these factors can significantly impact your business's productivity.

In addition, consider the specific needs of your business when selecting a pump. Assess the required specifications such as flow rate, pressure, and fluid type to ensure compatibility. Seeking advice from trusted suppliers can further aid in identifying the most suitable options tailored to your unique operational demands.

5 Essential Tips for Choosing the Right Commercial Pump for Your Business Needs

| Criteria | Description | Importance Rating (1-5) | Comments |

|---|---|---|---|

| Flow Rate | Ensure the pump meets the required flow rate for your specific application. | 5 | Critical for efficiency and operational success. |

| Head Pressure | Check the vertical lift capability to ensure it meets system needs. | 4 | Affects the performance in high-rise applications. |

| Energy Efficiency | Look for pumps that offer optimal energy consumption to reduce costs. | 5 | Direct impact on operational costs and sustainability. |

| Materials and Construction | Consider pump materials for compatibility with the liquid being pumped. | 4 | Prevents corrosion and extends pump life. |

| Supplier Reputation | Research supplier history and customer feedback for service reliability. | 5 | Vital for ensuring product quality and support availability. |

| Customer Support | Evaluate the level of ongoing support and service offered by the supplier. | 5 | Essential for troubleshooting and maintenance queries. |

| Warranty and Service Plans | Assess warranty provisions and available service agreements for long-term protection. | 4 | Provides security for investment and ongoing operational stability. |

Related Posts

-

The Future of Suction Pump Technology Revolutionizing Efficiency and Performance

-

Innovative Tank Mixer Applications Across Various Industries

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights