Blog

Understanding the Importance of Chemical Pumps in Modern Industrial Processes

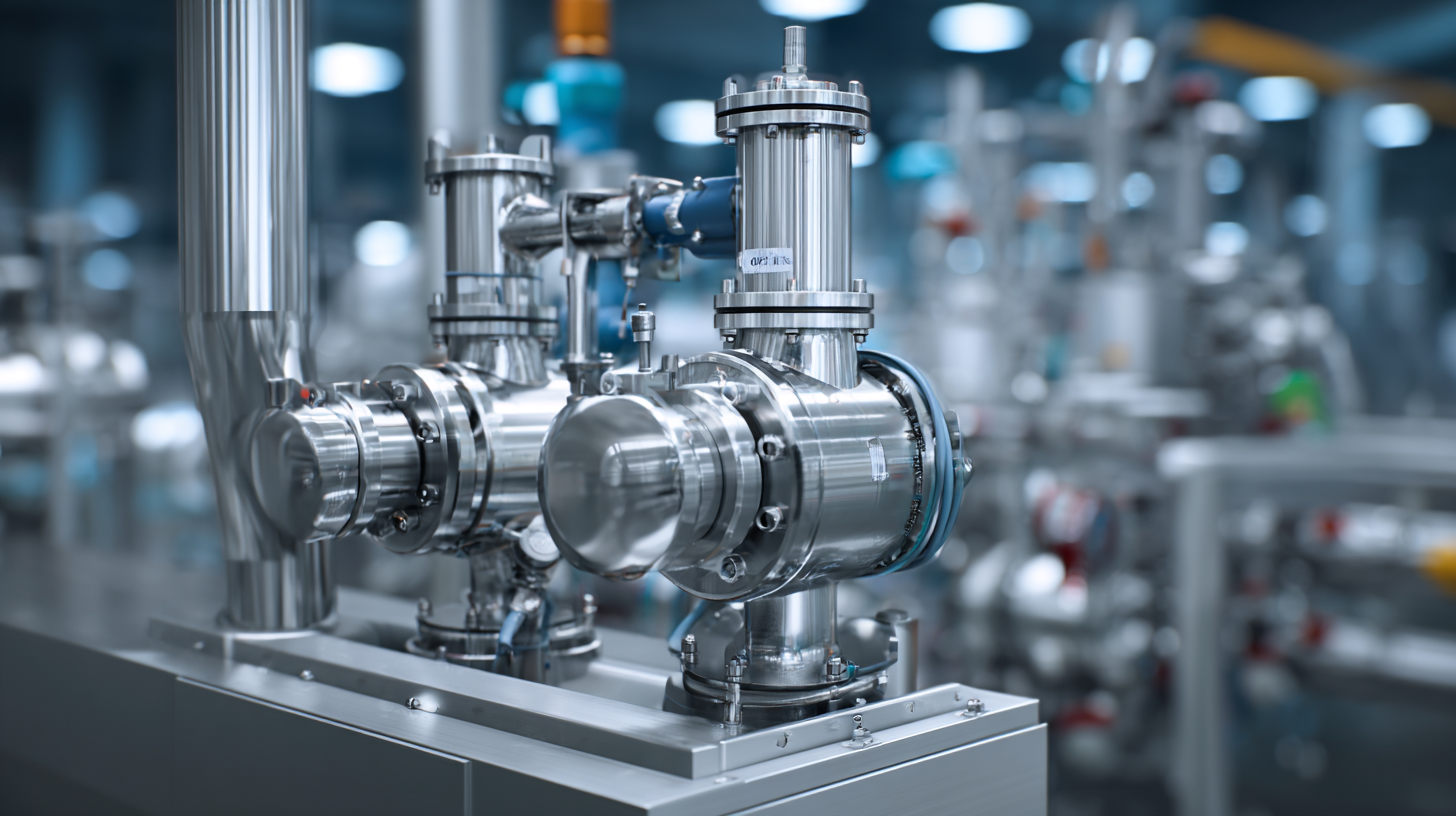

In the realm of modern industrial processes, the role of chemical pumps has become increasingly crucial. These specialized devices are designed to efficiently and safely transfer various types of fluids, including corrosive and viscous chemicals, which are often integral to manufacturing, processing, and treatment operations.

Understanding the importance of chemical pumps involves recognizing their pivotal contribution to efficiency, safety, and reliability in industries such as petrochemicals, pharmaceuticals, and water treatment. With a variety of designs and mechanisms available, chemical pumps can be tailored to meet specific operational requirements, ensuring optimal performance under varied conditions.

As industries evolve and face new challenges, the innovation and enhancement of chemical pump technology are essential in maintaining competitive advantages and achieving sustainable growth. This overview will delve into the different types of chemical pumps, their applications, and the critical factors that underscore their significance in contemporary industrial environments.

The Role of Chemical Pumps in Streamlining Industrial Operations

The significance of chemical pumps in modern industrial operations cannot be overstated. These pumps are essential in transferring and managing a wide variety of fluids, including corrosive chemicals and viscous materials, which are prevalent in various sectors such as pharmaceutical, petrochemical, and food processing. By efficiently moving substances from one point to another, chemical pumps help streamline production processes, reducing time and labor costs while ensuring a consistent flow of materials.

Moreover, the versatility of chemical pumps contributes to their pivotal role in enhancing operational efficiency. They can be tailored to meet specific needs, such as handling different fluid viscosities and chemical compositions, thereby minimizing the risk of equipment failure and downtime. Additionally, advanced technologies utilized in modern chemical pumps, such as smart monitoring systems, enable real-time assessments of pump performance and fluid parameters. This not only improves reliability but also allows manufacturers to optimize their operations, achieving a higher level of productivity and safety in their industrial processes.

Key Factors to Consider When Selecting Chemical Pumps for Your Facility

When selecting chemical pumps for industrial facilities, several key factors must be considered to ensure optimal performance and safety. One critical aspect is the pump material compatibility with the chemicals being handled. According to a report by the Fluid Handling Institute, approximately 60% of pump failures in chemical processing can be attributed to corrosion and material degradation. Facilities need to assess the chemical properties, including pH, temperature, and concentration, to choose the right materials that can withstand these conditions.

Another essential consideration is the pump's flow rate and pressure requirements. The American Society of Mechanical Engineers (ASME) suggests that understanding the specific flow rate and pressure needs can lead to more efficient processes and energy savings. A pump that is not properly sized may lead to increased operational costs and unnecessary wear and tear. Furthermore, the pump's energy efficiency plays a crucial role in long-term operational costs. The U.S. Department of Energy reports that energy-efficient pumps can reduce energy consumption by up to 50%, offering significant savings for industrial facilities while also supporting sustainability initiatives.

Innovative Technologies Enhancing the Efficiency of Chemical Pumps

Innovative technologies are pivotal in enhancing the efficiency of chemical pumps, which are essential for various industrial processes. According to a report by the International Pump Manufacturers Association (IPMA), advancements in smart technologies and automation have improved the operational efficiency of chemical pumps by up to 30%. These innovations include the integration of IoT (Internet of Things) sensors that provide real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs.

Furthermore, the adoption of advanced materials and designs has led to pumps that can handle more aggressive chemicals and operate under higher pressures without compromising safety. A study by Grand View Research indicates that the global chemical pump market is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030, driven by increased investments in process efficiency and sustainability. As companies seek to minimize energy consumption and reduce environmental impact, these technologies not only enhance the lifespan of chemical pumps but also contribute to more sustainable industrial practices.

Maintenance Tips to Maximize the Lifespan of Chemical Pumps

Chemical pumps play a crucial role in various industrial processes, particularly in the chemical, petroleum, and water treatment sectors. To ensure optimal performance and longevity of these pumps, adhering to proper maintenance practices is essential. According to a report from the Hydraulic Institute, nearly 60% of pump failures are attributed to improper maintenance, underscoring the need for regular inspections and upkeep.

One of the key maintenance tips is to perform routine checks for wear and tear on seals and bearings, as these components are vital for preventing leaks and maintaining efficiency. The American Society of Mechanical Engineers (ASME) suggests that regular monitoring of vibration levels can help identify potential issues before they escalate. Furthermore, ensuring that pumps are always operated within their designed capacities can significantly reduce the risk of damaging conditions that lead to premature deterioration. By implementing these maintenance strategies, industries can enhance the reliability of their chemical pumps and ultimately save on repair costs, thereby maximizing their operational output.

Understanding the Importance of Chemical Pumps in Modern Industrial Processes

This bar chart illustrates the average lifespan and failure rates of different types of chemical pumps commonly used in industrial processes. Regular maintenance can significantly enhance their longevity.

Safety Measures for Handling and Operating Chemical Pumps in Industries

Chemical pumps play a critical role in various industrial processes, facilitating the efficient and safe transfer of corrosive and hazardous liquids. Given their importance, strict safety measures must be implemented to protect both personnel and the environment. According to the Fluid Power Journal, nearly 30% of workplace incidents in chemical handling occur due to improper pump operation or maintenance. Utilizing appropriate personal protective equipment (PPE) like gloves and goggles is essential, as well as ensuring proper training for operators on the specific hazards posed by the chemicals being handled.

Furthermore, regular maintenance and inspection are crucial in minimizing the risks associated with chemical pumps. A report from the American National Standards Institute (ANSI) highlights that facilities employing proactive maintenance strategies report a 20% reduction in incident rates related to chemical handling. Considering the industry standards, it is recommended that organizations conduct routine checks on seals, motors, and piping systems to prevent leaks or failures. Implementing these safety measures not only safeguards employees but also enhances operational efficiency, mitigating potential losses from chemical spills or accidents.

Related Posts

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

How to Optimize Your Chemical Metering Pump for Maximum Efficiency