Blog

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control

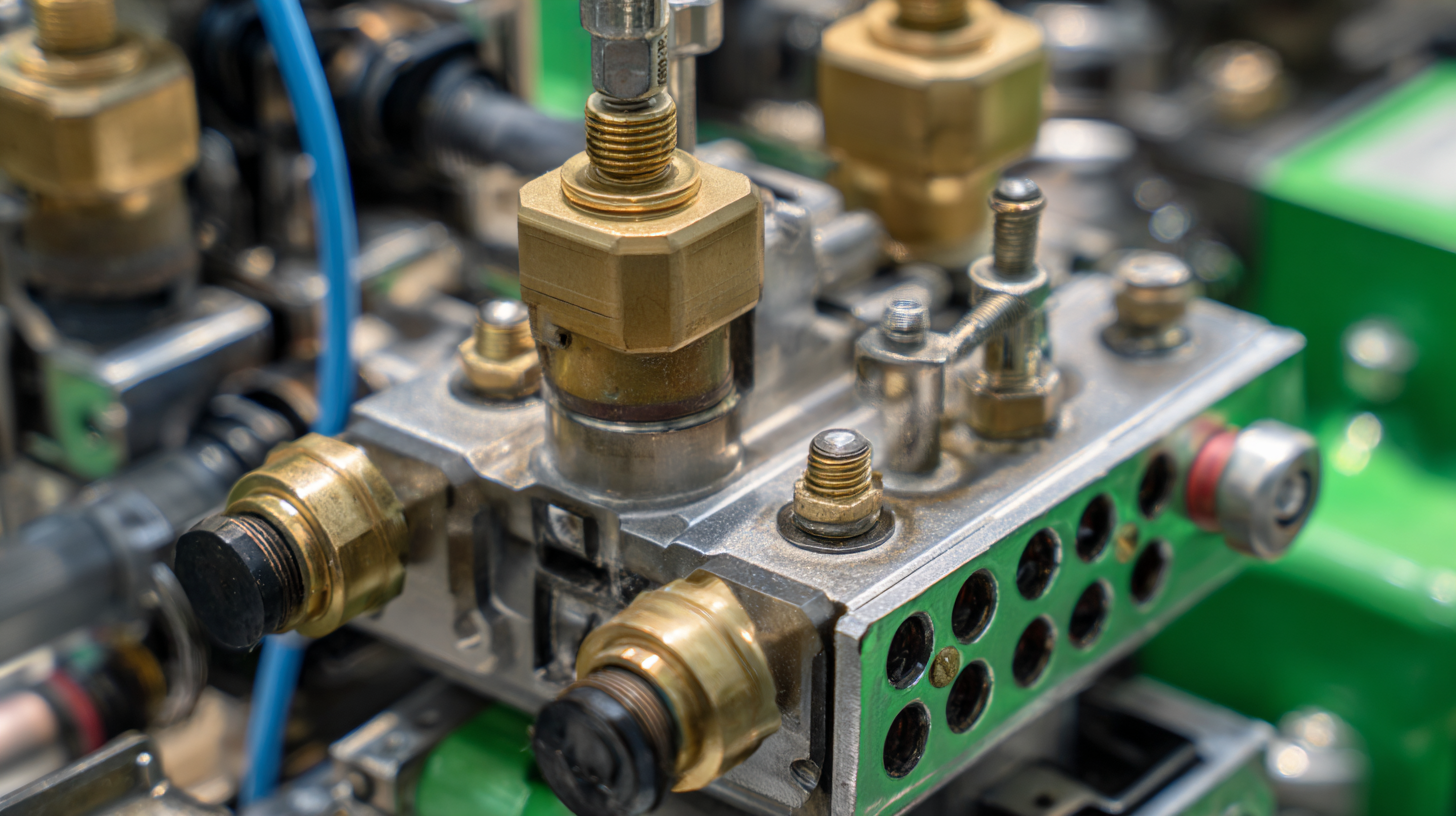

In the realm of precision fluid control, the diaphragm metering pump stands as a pivotal component for various industrial applications. Understanding the importance of this innovative technology is essential for engineers and operators seeking optimal performance in fluid management systems. Diaphragm metering pumps are renowned for their ability to deliver precise volumes of liquids under varying conditions, ensuring reliability and accuracy in processes ranging from chemical dosing to water treatment. Their design allows for minimal exposure of the pumped fluid to the environment, which greatly reduces contamination risks and enhances operational safety. Moreover, the versatility and efficiency of diaphragm metering pumps make them indispensable in sectors such as pharmaceuticals, food and beverage, and agriculture, where stringent quality controls are paramount. As industries strive for more efficient and sustainable practices, grasping the significance of diaphragm metering pumps will undoubtedly contribute to achieving these goals.

The Role of Diaphragm Metering Pumps in Accurate Fluid Delivery

Diaphragm metering pumps play a crucial role in ensuring accurate fluid delivery across various industries, including pharmaceuticals, chemical processing, and water treatment. These pumps offer precise flow rates, which are essential for maintaining the quality and consistency of products. According to a report by Grand View Research, the global diaphragm pump market is projected to exceed $6 billion by 2025, driven by the growing demand for precision fluid control systems. This underscores the importance of diaphragm metering pumps in sectors where accuracy is non-negotiable.

The technology behind diaphragm metering pumps enables them to handle a wide range of fluids, from corrosive liquids to viscous substances, with exceptional precision. A study by the Technical University of Munich indicated that diaphragm metering pumps reduce flow rate deviations to less than 1%, significantly enhancing operational efficiency. This level of accuracy not only minimizes waste but also improves the reliability of fluid transfers, making these pumps an indispensable tool for industries that require stringent regulatory compliance and uncompromised product integrity.

Understanding the Importance of Diaphragm Metering Pumps in Precision Fluid Control

| Application | Flow Rate (L/h) | Pressure (bar) | Fluid Type | Accuracy (%) |

|---|---|---|---|---|

| Wastewater Treatment | 200 | 4 | Chemicals | ±1 |

| Food Processing | 150 | 2 | Food Additives | ±0.5 |

| Pharmaceuticals | 100 | 5 | Drugs | ±0.1 |

| Agriculture | 250 | 3 | Fertilizers | ±2 |

| Chemical Processing | 300 | 6 | Acids and Bases | ±1.5 |

Key Features of Diaphragm Metering Pumps for Precision Applications

Diaphragm metering pumps play a crucial role in various precision fluid control applications, thanks to their ability to deliver consistent flow rates and handle a wide range of fluids. One of their key features is the capability to accurately dispense small volumes of fluid while maintaining precise pressure levels. This accuracy is essential in industries such as pharmaceuticals, water treatment, and chemical processing, where even slight deviations can lead to significant consequences.

When selecting a diaphragm metering pump, it’s essential to consider factors such as pump material compatibility, flow rate, and pressure range. Additionally, employing these pumps with appropriate monitoring systems can greatly enhance control over the dosing process.

Tip: Regular maintenance of diaphragm metering pumps helps in preserving their performance and prolonging their lifespan. Always check for wear and tear of the diaphragm and ensure proper calibration to maintain accuracy.

Furthermore, the ability to easily adjust the flow rate makes these pumps ideal for dynamic applications where fluid demands may fluctuate. Utilizing automatic controls can optimize both efficiency and consistency, ensuring that operations run smoothly and without interruptions.

Tip: Implementing a visual control system will allow operators to monitor performance in real-time, quickly identifying any deviations from desired flow rates.

Applications of Diaphragm Metering Pumps in Various Industries

Diaphragm metering pumps play a critical role in various industries due to their ability to provide precise fluid control. In the pharmaceutical sector, these pumps are essential for dosing active ingredients in drug formulations, ensuring consistency and accuracy that are vital for patient safety and efficacy. Their ability to handle hazardous chemicals safely further enhances their appeal in this sensitive field, reducing risks associated with leaks or contamination.

Diaphragm metering pumps play a critical role in various industries due to their ability to provide precise fluid control. In the pharmaceutical sector, these pumps are essential for dosing active ingredients in drug formulations, ensuring consistency and accuracy that are vital for patient safety and efficacy. Their ability to handle hazardous chemicals safely further enhances their appeal in this sensitive field, reducing risks associated with leaks or contamination.

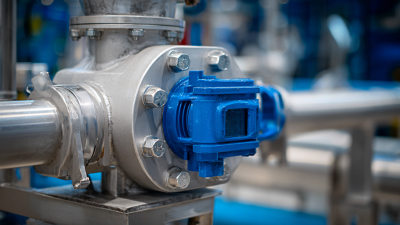

In water treatment facilities, diaphragm metering pumps facilitate the accurate injection of chemicals such as chlorine and coagulants, crucial for maintaining water quality. The pumps allow for fine-tuning of chemical dosing based on real-time water quality analysis, thereby optimizing treatment processes and reducing waste. Similarly, in the food and beverage industries, they ensure accurate ingredient blending and flavoring. The ability to handle sanitary applications while preventing contamination makes diaphragm metering pumps an indispensable tool in maintaining the integrity of consumable products.

Comparative Advantages of Diaphragm Pumps Over Other Metering Technologies

Diaphragm metering pumps play a crucial role in precision fluid control applications, especially within industries such as water treatment, chemical processing, and food production. One of the major advantages of diaphragm pumps over traditional metering technologies, such as gear or peristaltic pumps, lies in their ability to maintain accurate flow rates while handling highly viscous or corrosive fluids safely. According to a report by MarketsandMarkets, the diaphragm pump market is expected to witness significant growth, anticipated to reach USD 5.8 billion by 2025, driven by the increasing demand for precise fluid handling solutions.

Moreover, diaphragm pumps exhibit superior chemical compatibility and leak-free operation, making them ideal for sensitive applications. Unlike gear pumps, which can experience shear and heat-related issues affecting fluid properties, diaphragm pumps maintain the integrity of the fluid being transferred. A study published in the International Journal of Chemical Engineering highlights that diaphragm pumps can achieve flow accuracy levels within ±1%, a significant improvement over the ±3-5% accuracy standard found in many competitive metering technologies. This level of precision is essential for industries where exact dosages are critical, underscoring the growing preference for diaphragm metering pumps in precision fluid control.

Future Trends in Diaphragm Metering Pump Technology and Fluid Control Solutions

The landscape of diaphragm metering pump technology is evolving rapidly, driven by advancements in precision fluid control solutions. According to the latest report from Technavio, the global metering pump market is expected to grow by approximately 7.5% annually from 2021 to 2025, highlighting a significant demand for more efficient and reliable fluid management systems. As industries increasingly seek automation and optimized performance, diaphragm metering pumps are at the forefront, offering exceptional accuracy in dispensing viscous and corrosive liquids.

Future trends indicate a shift toward smart metering solutions that integrate IoT technology for enhanced monitoring and control. A report by Market Research Future suggests that the adoption of smart diaphragms, which can adjust flow rates in real-time based on feedback from sensors, will boost operational efficiency and reduce waste. This innovation not only contributes to sustainability goals but also aligns with stricter regulatory standards in sectors like pharmaceuticals and water treatment. As companies invest in these cutting-edge technologies, they are set to benefit from lower operating costs and improved product quality, further cementing diaphragm metering pumps as critical components in advanced fluid control systems.

Related Posts

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

How to Choose the Right Chemical Diaphragm Pump for Your Application

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Innovative Applications of Diaphragm Pumps Across Various Industries

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

Maximizing Efficiency: How Chemical Feed Pumps Improve Industrial Process Control