Blog

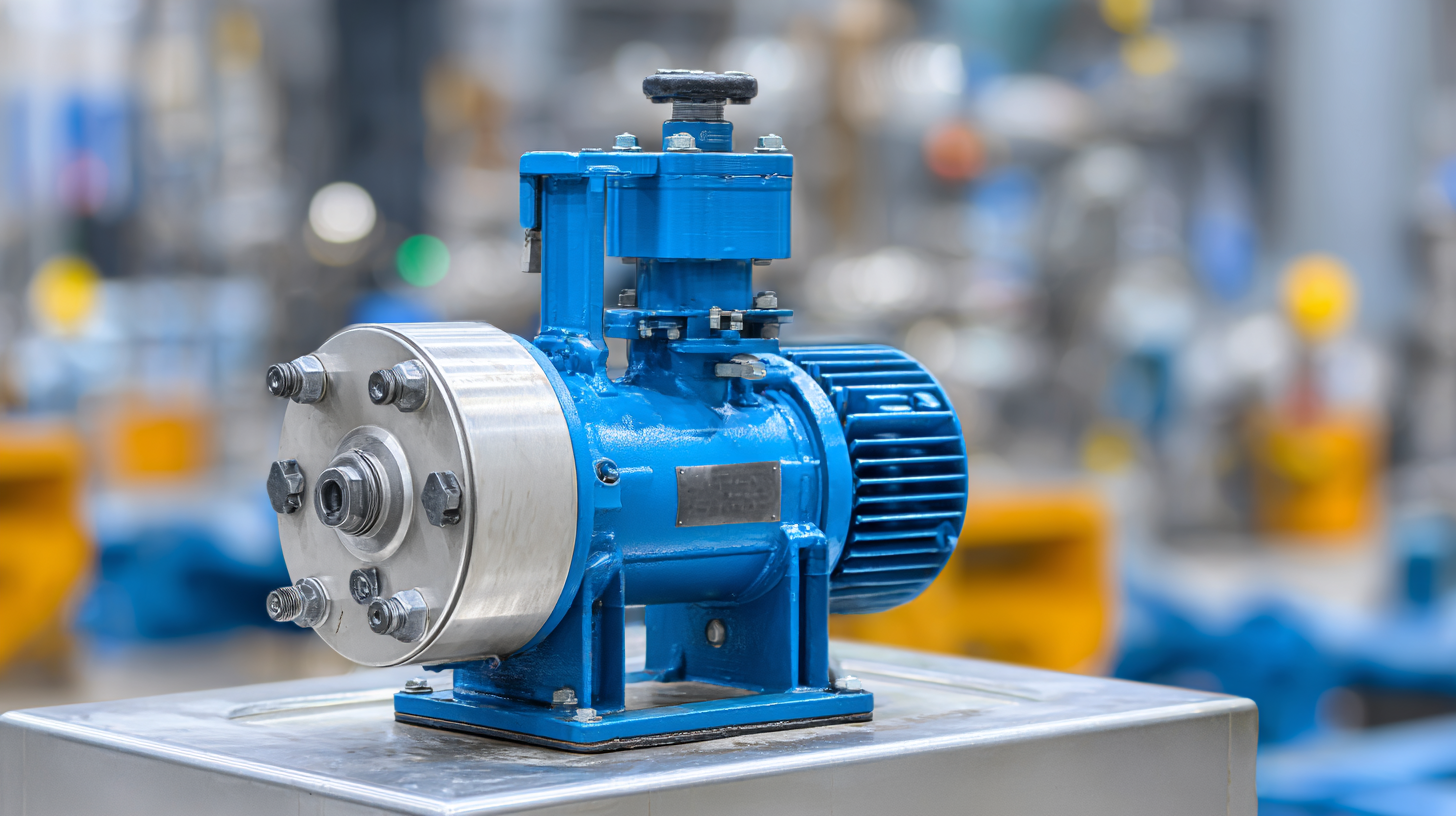

How to Optimize Your Chemical Metering Pump for Maximum Efficiency

In the increasingly competitive landscape of the chemical industry, optimizing the performance of chemical metering pumps has become essential for enhancing operational efficiency and reducing costs. According to a recent report from MarketsandMarkets, the global market for chemical metering pumps is projected to reach USD 5.7 billion by 2025, growing at a CAGR of 5.6%. This growth underscores the critical role that these devices play in applications ranging from water treatment to chemical processing. Proper optimization of chemical metering pumps not only ensures accurate dosing and consistency in production but also contributes to improved energy efficiency and reduced waste. By implementing best practices and leveraging the latest technological advancements, businesses can maximize the effectiveness of their chemical metering pumps while meeting stringent environmental regulations and market demands.

Identifying Key Parameters for Chemical Metering Pump Performance

To optimize the performance of a chemical metering pump, it is crucial to identify and evaluate several key parameters. One critical factor is the pump's flow rate, which must align with the specific application requirements. This involves assessing the viscosity and density of the chemical being pumped, as they can significantly affect the accuracy and efficiency of the delivery. Increasing the flow rate beyond the recommended limits may lead to undesirable pulsation and reduced accuracy, prompting the need for fine-tuning adjustments.

Another essential parameter is the pressure at which the pump operates. Maintaining the appropriate pressure ensures that the chemicals are delivered consistently and uniformly. Analyzing the system's total dynamic head (TDH) also offers insights into the effectiveness of the pump in overcoming the pressure necessary to transport the chemicals. Additionally, regular monitoring of seal conditions and the wear of components, such as diaphragms and valves, will assist in maintaining optimal performance and preventing potential leaks, which can impact efficiency and safety. Proper calibration and routine maintenance based on these parameters can lead to a significant increase in the overall efficiency of chemical metering pumps.

Regular Maintenance Practices to Enhance Pump Efficiency

Regular maintenance practices are essential for enhancing the efficiency of chemical metering pumps. According to a study by the Hydraulic Institute, proper maintenance can improve pump efficiency by up to 25%, significantly reducing operational costs over time. One of the primary maintenance tasks is to regularly check and replace worn seals and diaphragms, as these components can significantly affect the pump's ability to maintain accurate flow rates. The American Society of Mechanical Engineers (ASME) recommends implementing a scheduled maintenance plan that includes routine inspections and testing of the pump's performance metrics, as neglected maintenance can lead to increased energy consumption and premature pump failure.

In addition to replacing worn parts, it's crucial to monitor the pump's alignment and vibration levels. The International Society for Automation (ISA) reports that misalignment can lead to a 20-30% drop in efficiency. Regularly calibrating the pump to ensure it meets manufacturer specifications can also prevent excessive wear and tear. Moreover, keeping accurate records of maintenance activities and performance data helps identify trends that may indicate underlying issues, allowing for proactive interventions. By adhering to these regular maintenance practices, operators can optimize the performance of their chemical metering pumps, ultimately leading to improved efficiency and reduced downtime.

Choosing the Right Pump Type for Specific Chemical Applications

When it comes to chemical applications, choosing the right metering pump type is crucial for optimizing efficiency and performance. Different chemical properties—such as viscosity, temperature, and corrosiveness—inform the selection process. According to a report by the Chemical Engineering Magazine, using the correct type of pump can improve application efficiency by up to 20%, illustrating the importance of this decision.

For instance, diaphragm pumps are highly suitable for handling corrosive chemicals, as they provide a leak-free operation and maintain precise flow rates. Conversely, gear pumps are often preferred for their ability to convey high-viscosity fluids, with a performance range typically exceeding 500 GPH (gallons per hour) in specific industrial settings. The 2022 Pump Industry Benchmark Report indicates that failing to select the appropriate pump type could lead to significant increases in operational costs, often exceeding 15% annually due to inefficiencies and maintenance issues. Thus, a thorough understanding of chemical characteristics and pump capabilities is essential for maximizing efficiency in metering applications.

Calibrating Flow Rates to Maximize Delivery Accuracy

Calibrating flow rates is crucial for achieving maximum delivery accuracy in chemical metering pumps. Proper calibration ensures that the pump dispenses the exact volume of chemicals required for specific applications, minimizing waste and preventing over- or under-dosing. To begin the calibration process, it is essential to determine the desired flow rate based on the operational requirements. This involves evaluating factors such as the type of chemical being pumped, the desired concentration in the mixture, and the overall system dynamics.

Once the target flow rate is established, the next step involves adjusting the pump settings accordingly. This may require fine-tuning the pump speed or the stroke length to achieve the desired output. Regular testing under actual working conditions is essential to verify that the pump delivers accurate and consistent flow rates. By meticulously calibrating the pump and routinely monitoring its performance, operators can greatly enhance the efficiency of their metering systems, ensuring optimal chemical usage and cost-effectiveness while also maintaining safety standards.

Optimizing Chemical Metering Pump Efficiency

This chart represents the delivery accuracy of a chemical metering pump at different flow rates. The goal is to identify optimal flow rates to enhance overall efficiency.

Implementing Smart Technology for Real-Time Efficiency Monitoring

Implementing smart technology for real-time efficiency monitoring in chemical metering pumps can significantly enhance operational performance. The integration of Internet of Things (IoT) technologies, which have been widely adopted across various sectors, allows for continuous data collection and analysis, leading to proactive maintenance and operational adjustments. For example, studies have shown that real-time monitoring enabled by IoT can improve resource management by up to 30%, optimizing the processes involved in chemical dosing applications.

Moreover, the use of advanced sensor technologies in smart factories reveals that real-time performance analytics can drive manufacturing efficiency, contributing to a 20% reduction in operational costs. By equipping chemical metering pumps with smart sensors, operators can receive instant feedback on their performance metrics, allowing for quicker adjustments and minimizing downtime. This evolution not only promotes sustainable practices in industries but also aligns with broader trends observed in precision agriculture and smart city initiatives, where digital tools are key to driving efficiency and innovation.

How to Optimize Your Chemical Metering Pump for Maximum Efficiency - Implementing Smart Technology for Real-Time Efficiency Monitoring

| Parameter | Value | Unit | Remarks |

|---|---|---|---|

| Flow Rate | 150 | L/h | Target range achieved |

| Pressure | 3.5 | bar | Stable operation |

| Energy Consumption | 1.2 | kW | Optimized using smart technology |

| Maintenance Frequency | 6 | months | Regular monitoring recommended |

| Operational Efficiency | 95 | % | Maximized through monitoring |

Related Posts

-

7 Essential Features of the Best Chemical Metering Pumps for Global Buyers

-

5 Unmatched Benefits of Using Chemical Metering Pumps for Precision in Industry

-

How to Choose the Right Chemical Metering Pump for Your Industry Needs

-

5 Best Practices for Choosing the Right Chemical Feed Pump

-

Exploring Market Trends for Chemical Feed Pumps at the 138th Canton Fair 2025 in China

-

Innovative Applications of Diaphragm Pumps Across Various Industries