Blog

How to Optimize Pump Technology for Increased Efficiency and Reduced Costs

In the quest for enhanced operational efficiency and cost reduction, optimizing pump technology has emerged as a critical focal point for industries worldwide. According to the U.S. Department of Energy, pumps account for nearly 20% of the global electricity consumption, signifying the urgency to innovate and implement more energy-efficient designs and technologies. Modern advancements in pump efficiency can result in energy savings of 15% or more, translating to substantial reductions in operational costs.

Evaluating the Life Cycle Costs of Pump Systems for Enhanced Efficiency

Evaluating the life cycle costs (LCC) of pump systems is crucial for enhancing operational efficiency and reducing overall expenses. According to a report by the Hydraulic Institute, nearly 20-30% of a pump's life cycle cost comes from energy consumption alone, highlighting the importance of energy-efficient designs. By assessing factors such as installation, maintenance, and utility costs, businesses can make informed decisions that lead to significant long-term savings.

Evaluating the life cycle costs (LCC) of pump systems is crucial for enhancing operational efficiency and reducing overall expenses. According to a report by the Hydraulic Institute, nearly 20-30% of a pump's life cycle cost comes from energy consumption alone, highlighting the importance of energy-efficient designs. By assessing factors such as installation, maintenance, and utility costs, businesses can make informed decisions that lead to significant long-term savings.

Tips: Regularly audit your pump systems to identify areas requiring optimization. Utilize advanced monitoring technologies to track performance metrics, as these can provide insights into energy usage and maintenance needs, thus extending the operational life of the pump.

Moreover, implementing variable frequency drives (VFDs) can improve pump efficiency by up to 50%. A recent study from the U.S. Department of Energy indicated that properly sized and controlled VFDs lead to a significant reduction in energy usage. By focusing on LCC analysis, companies can pinpoint upgrades necessary for modernizing existing systems, ultimately resulting in reduced operational costs and enhanced performance.

Tips: Engage in training for operational staff on the latest technologies and best practices for maintenance and monitoring, ensuring a culture of efficiency and continuous improvement within your organization.

Implementing Variable Speed Drives to Optimize Pump Performance and Energy Savings

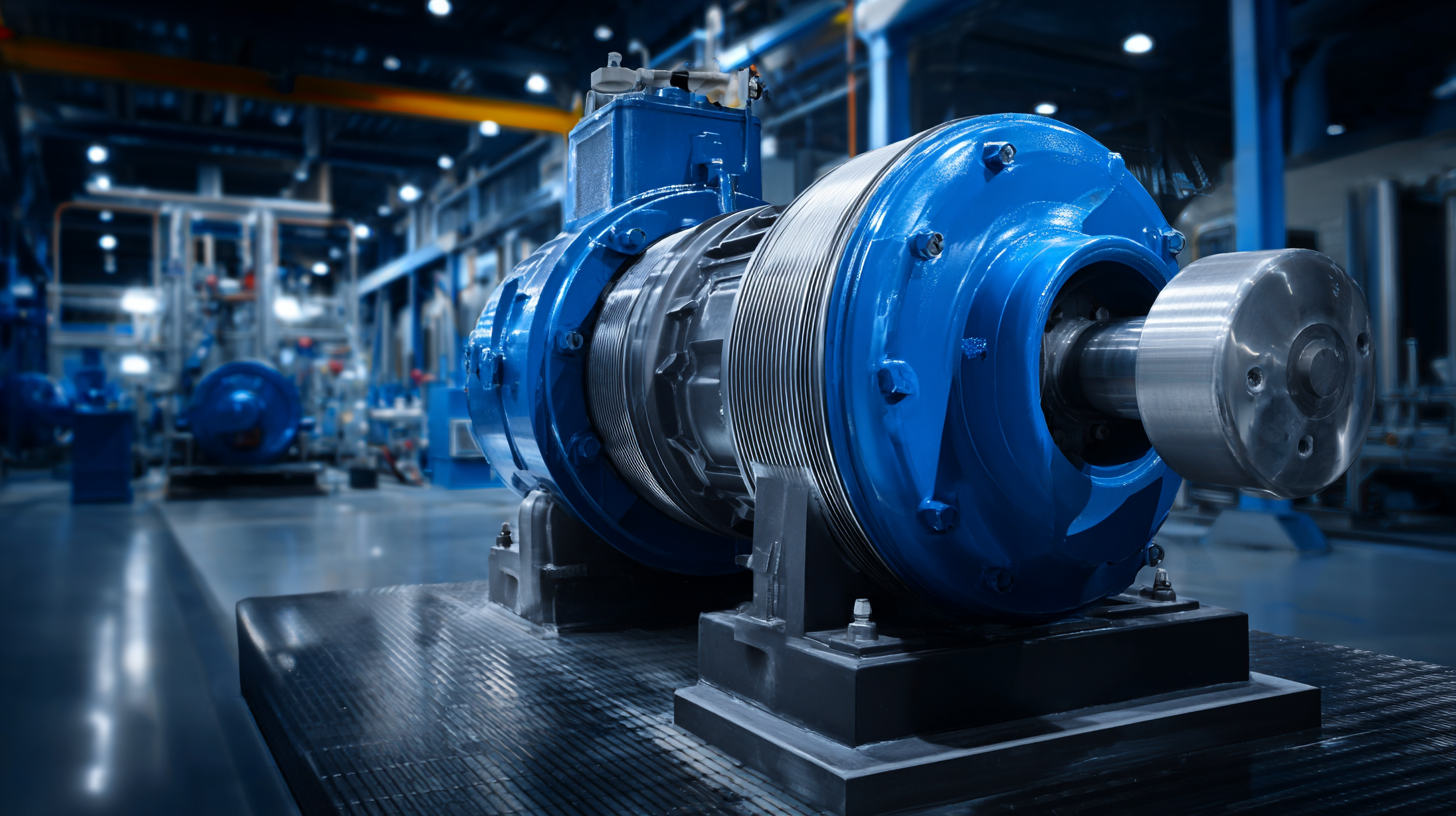

Implementing Variable Speed Drives (VSDs) is a game changer for optimizing pump technology. VSDs allow pumps to adjust their speed based on the actual demand of the system, leading to significant energy savings and enhanced performance. By controlling the pump speed, facilities can avoid operating at full capacity when it’s unnecessary, ultimately resulting in lower operational costs. The integration of VSDs not only improves energy efficiency but also extends the lifespan of the equipment by reducing wear and tear on pump components.

**Tips for Implementation:**

- Conduct a thorough analysis of your current pump operations to identify opportunities for speed adjustment.

- Ensure compatibility between the VSD and existing pumps to prevent malfunctions and optimize performance.

- Regularly monitor system performance post-implementation to evaluate energy savings and make necessary adjustments.

Incorporating VSD technology can lead to a drastic reduction in energy consumption, making it an essential investment for businesses aiming to enhance their pump systems. With the right approach, facilities can experience reliable pump performance while simultaneously lowering their energy costs and promoting sustainability.

Benchmarking Pump Efficiency: Key Metrics and Standards for Industry Best Practices

Benchmarking pump efficiency is essential for industries seeking to enhance operational performance and reduce costs. According to an industry report by the Hydraulic Institute, optimizing pump systems can lead to energy savings of up to 25%. This is particularly critical as energy costs continue to rise, making it imperative for companies to assess their pump efficiency regularly. Key metrics such as flow rate, head, and power consumption should be analyzed to ensure that pumps operate within optimal parameters.

In addition to standard performance metrics, adherence to established industry standards, such as those set by ISO 9906 for pump testing, is crucial. These benchmarks not only provide a framework for evaluating pump performance but also facilitate compliance and help in identifying areas for improvement. Reports indicate that companies that implement standardized efficiency metrics could potentially save millions annually in operational costs while reducing carbon footprints. Therefore, adopting industry best practices in benchmarking pump efficiency not only enhances productivity but also aligns with sustainability goals.

Utilizing Predictive Maintenance Strategies to Reduce Downtime and Operational Costs

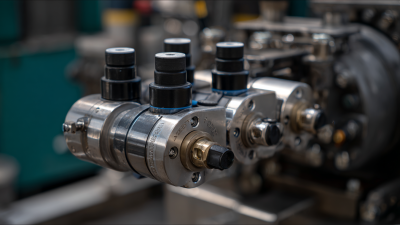

Predictive maintenance strategies are becoming essential in optimizing pump technology for improved efficiency and reduced operational costs. By leveraging advanced analytics and real-time monitoring, companies can anticipate potential failures before they occur. This proactive approach allows maintenance teams to address mechanical issues during scheduled downtimes, thus minimizing unplanned outages that typically lead to significant financial losses.

Furthermore, implementing predictive maintenance not only enhances the lifespan of pump equipment but also improves overall system reliability. By continuously collecting and analyzing data from various pump components, operators can gain insights into performance trends and operational inefficiencies. This information enables them to adjust processes promptly, ensuring that pumps operate at their optimal capacity while reducing energy consumption. Ultimately, integrating predictive maintenance into pump management strategies supports a sustained competitive advantage in an increasingly cost-sensitive marketplace.

How to Optimize Pump Technology for Increased Efficiency and Reduced Costs

| Parameter | Current Value | Target Value | Action Plan |

|---|---|---|---|

| Pump Efficiency (%) | 75 | 85 | Implement regular maintenance and upgrades |

| Annual Operating Cost ($) | 50000 | 40000 | Adopt predictive maintenance strategies |

| Downtime (Hours/Year) | 120 | 30 | Use IoT sensors for real-time monitoring |

| Water Consumption (Cubic Meters/Year) | 15000 | 12000 | Enhance system design for lower water use |

| Maintenance Frequency (Times/Year) | 4 | 6 | Increase inspections based on predictive analytics |

Integrating Advanced Materials and Coatings for Improved Pump Durability and Efficiency

The integration of advanced materials and coatings in pump technology is revolutionizing the efficiency and durability of these essential devices. Recent studies indicate that the use of enhanced materials, such as high-performance polymers and composites, can reduce wear and tear, leading to an increase in pump life by up to 30%. For instance, the American Society for Testing and Materials (ASTM) has reported that pumps utilizing advanced ceramic coatings experience less erosion and corrosion, significantly boosting operational reliability in aggressive fluid handling applications.

Additionally, innovations in coating technologies, such as nanocoatings and specialized polymer blends, are proving to be game-changers. A report from the Hydraulic Institute suggests that incorporating such coatings can improve energy efficiency by as much as 15% due to reduced friction and enhanced hydrodynamic performance. As industries strive for cost-effective solutions, the adoption of these cutting-edge materials not only supports sustainability efforts but also translates into lower maintenance costs, ultimately benefiting the bottom line. The data reflects a pivotal shift towards embracing advanced materials as a key avenue for optimizing pump performance while addressing the economic pressures faced by various sectors.

Optimization of Pump Technology: Efficiency vs. Cost

Related Posts

-

5 Essential Tips for Choosing the Right Commercial Pump for Your Business Needs

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights

-

Essential Tank Mixer Guide: Mastering Mixing Techniques for Optimal Results

-

The Future of Suction Pump Technology Revolutionizing Efficiency and Performance

-

How to Select the Right Injection Pumps for Your Industrial Needs

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs