Blog

10 Unique Metering Pump Types You Should Know About

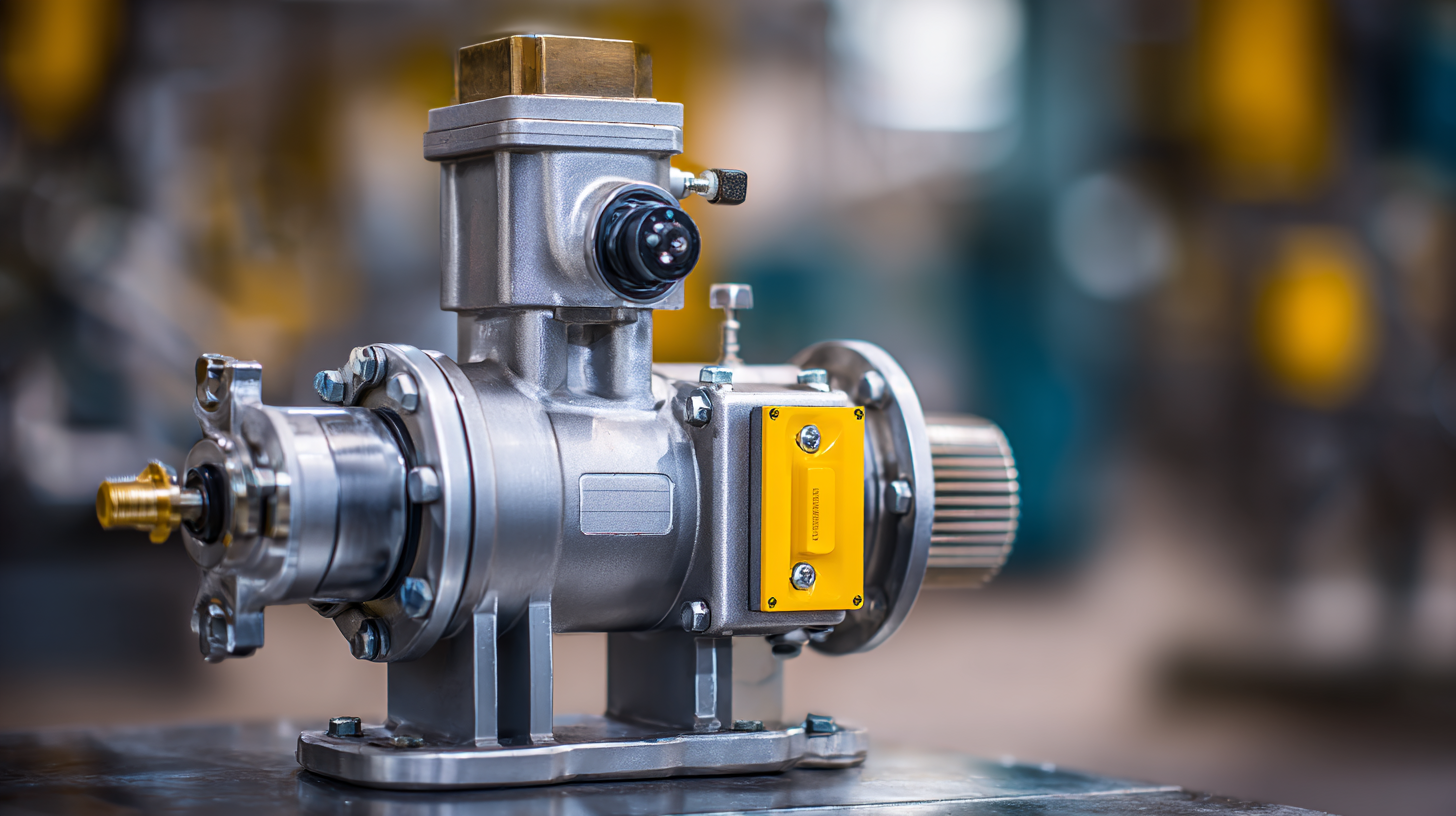

Metering pumps are essential devices in various industries, responsible for precisely displacing and delivering a specific amount of liquid or chemical in a controlled manner. Understanding the different metering pump types available in the market is crucial for selecting the right one to meet specific operational needs.

This article will explore ten unique metering pump types that showcase the diversity and functionality of these pumps across applications such as water treatment, pharmaceuticals, and food processing. By examining features, advantages, and typical uses of each design, we aim to equip you with the knowledge required to make informed decisions.

Whether you are an engineer, a procurement specialist, or simply someone interested in pump technology, this overview of metering pump types will provide valuable insights into optimizing processes and improving efficiency.

Types of Positive Displacement Metering Pumps and Their Applications

Positive displacement metering pumps are essential in various industries where precise fluid control is critical. These pumps operate by trapping a fixed amount of fluid and then forcing it out, making them ideal for applications requiring accurate measurements. One common type is the diaphragm pump, known for its ability to handle corrosive fluids while providing a reliable seal. This makes it particularly useful in the chemical and pharmaceutical industries.

Another notable type is the gear pump, which utilizes rotating gears to move fluids. Gear pumps excel in handling high-viscosity liquids, making them a preferred choice in food processing and lubrication applications. Additionally, peristaltic pumps, which rely on the compression and relaxation of a flexible tube, are often used in medical and laboratory settings due to their gentle handling of sensitive fluids. Each type of positive displacement metering pump has unique features that cater to specific operational requirements, ensuring efficient and precise fluid metering across various sectors.

Exploring Solenoid-Driven Metering Pumps: Features and Benefits

Solenoid-driven metering pumps are essential components in various industrial applications, providing precise control over fluid dosing and delivery. These pumps utilize electromagnetic solenoids to regulate the flow of fluids, allowing for accurate and adjustable flow rates. Their design often includes features such as leak-proof construction, simplified maintenance, and the ability to handle a wide range of fluids, from corrosive materials to viscous substances. The versatility and reliability of solenoid-driven metering pumps make them invaluable in sectors like pharmaceuticals, water treatment, and chemical processing.

Recent advancements in metering pump technology further enhance their performance and sustainability. Innovations like the latest peristaltic metering pumps demonstrate improvements in flow rates and pressure capabilities, meeting the rising demands of efficiency and eco-friendliness. Dosing pump technologies now focus on smarter, more efficient operations to support water security initiatives. These developments not only improve the operational efficiency of wastewater treatment systems but also contribute to a more sustainable future by promoting the use of advanced, eco-conscious pumping solutions.

10 Unique Metering Pump Types You Should Know About

| Pump Type | Drive Type | Flow Rate Range | Applications | Key Features |

|---|---|---|---|---|

| Diaphragm Pump | Mechanical | 0.1 - 100 L/h | Water Treatment | Leak-proof, High accuracy |

| Solenoid-Driven Pump | Solenoid | 1 - 50 L/h | Chemical Dosing | Compact, Versatile |

| Peristaltic Pump | Mechanical | 0.1 - 400 L/h | Food Processing | Self-priming, Gentle handling |

| Gear Pump | Mechanical | 0.5 - 300 L/h | Oil Transfer | High pressure, Consistent flow |

| Piston Pump | Mechanical | 1 - 200 L/h | Pharmaceuticals | High precision, Durable |

Peristaltic Metering Pumps: A Versatile Solution for Fluid Transfers

Peristaltic metering pumps are a preferred choice for fluid transfer applications due to their unique design and operational flexibility. These pumps utilize a series of rollers or shoes that compress a flexible tube, creating a vacuum that draws fluid into the tube and then pushes it out with precision. This mechanism not only ensures accurate metering but also minimizes the risk of contamination, making them ideal for handling sensitive fluids, such as chemicals, pharmaceuticals, and food products.

Peristaltic metering pumps are a preferred choice for fluid transfer applications due to their unique design and operational flexibility. These pumps utilize a series of rollers or shoes that compress a flexible tube, creating a vacuum that draws fluid into the tube and then pushes it out with precision. This mechanism not only ensures accurate metering but also minimizes the risk of contamination, making them ideal for handling sensitive fluids, such as chemicals, pharmaceuticals, and food products.

One of the significant advantages of peristaltic pumps is their ability to handle a wide range of viscosities and flow rates. The gentle pumping action reduces shear stress on the fluid, preserving the integrity of delicate substances. Furthermore, their simple construction allows for easy maintenance and quick tube replacement, enhancing operational efficiency. With the capacity to self-prime and run dry without damage, peristaltic metering pumps prove to be a versatile and reliable solution for various applications, from laboratory settings to industrial processes.

Diaphragm Metering Pumps: Precision and Reliability in Chemical Dosing

Diaphragm metering pumps are widely recognized for their precision and reliability in chemical dosing applications, making them essential in various industries such as water treatment, pharmaceuticals, and food processing. According to a recent market analysis report by Grand View Research, the global diaphragm metering pump market is projected to reach USD 1.8 billion by 2026, growing at a CAGR of 6.5% due to the increasing demand for effective chemical dosing solutions.

These pumps operate by using a flexible diaphragm that creates a vacuum to draw in fluid and then pushes it out with controlled pressure, ensuring consistent flow rates even under varying conditions. This feature is particularly important in industries where chemical dosage accuracy can significantly impact product quality and safety. The report from Research and Markets highlights that diaphragm metering pumps can achieve repeatability within ±1% of the set point, making them a preferred choice for applications requiring high dosing accuracy.

Moreover, diaphragm metering pumps offer the benefit of handling highly viscous and corrosive fluids without compromising performance. With advancements in materials and design, manufacturers are now producing pumps that can handle pressures up to 150 bar, allowing for greater versatility across applications. This adaptability, coupled with their cost-effectiveness and low maintenance requirements, positions diaphragm metering pumps as a reliable choice for engineers and operators aiming to optimize their chemical dosing processes.

Gear Pumps: Understanding Their Unique Advantages for Metering Tasks

Gear pumps are becoming increasingly popular for metering tasks due to their ability to handle complex processes with precision and reliability. As industries such as automotive and furniture manufacturing integrate more polyurethane (PUR) into their products, the demand for efficient metering solutions grows. Gear pumps offer unique advantages, including a smooth and consistent flow, making them ideal for applications where accuracy is critical. According to industry reports, gear metering pumps can minimize material waste by 10-20%, leading to significant cost savings and improved production efficiency.

When considering gear pumps for metering applications, it’s essential to choose the right design for your specific needs. Tip: Always evaluate the pump's compatibility with the materials you'll be working with, especially if you are using viscous fluids or chemicals. Furthermore, ensure that you conduct regular maintenance to keep your pumps operating at peak performance.

In addition to their efficiency, gear pumps are known for their durability and low maintenance requirements. Tip: Opt for models equipped with wear-resistant materials to extend service life and reduce downtime. This will not only enhance the reliability of your manufacturing processes but also support sustainable production practices by minimizing the need for replacements and repairs.

10 Unique Metering Pump Types: Advantages of Gear Pumps

Related Posts

-

5 Essential Benefits of Using a Chemical Mixer for Your Manufacturing Process

-

Innovative Solutions for Industrial Pumps to Enhance Efficiency and Reduce Costs

-

Ultimate Guide to Choosing the Right Chemical Mixer: Key Features and Industry Insights

-

Comprehensive Guide to Selecting the Right Diaphragm Pump: Key Industry Insights and Performance Metrics

-

7 Essential Tips for Choosing the Right Chemical Mixer for Your Industry Needs

-

How to Optimize Pump Technology for Increased Efficiency and Reduced Costs